User Guide

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

Add this page to your book

Add this page to your book  Remove this page from your book

Remove this page from your book There is an alternative way to replenish your stock – through intersite transfers.

The purpose of intersite optimization is to help you release some frozen capital internally and replenish your inventory using your own overstocks before making any more replenishment orders (from supplier or DC).

In this article we describe the method used to generate intersite transfers and give a description of the Intersite optimization tab.

Let's describe a basic method used to generate intersite transfers. It consists of the following steps:

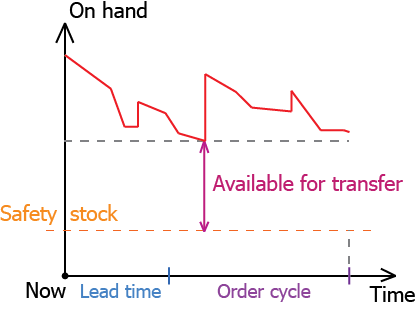

1. First, Streamline determines a list of planning items whose on-hand can be used to replenish other stores. For a planning item, the amount available for transfer is the minimal expected overstock amount during the Lead time plus Order cycle period (see figure below).

This quantity is found via event-based simulation of the future inventory movements. Let's denote it as Qty available for transfer and the list of found items as Replenish-from list.

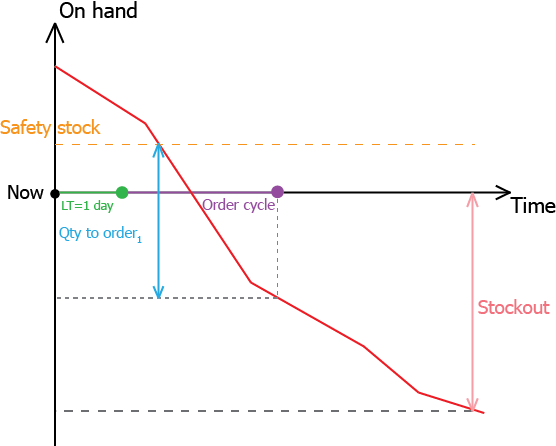

2. Then, Streamline finds a list of planning items that either have stockouts or need to be replenished from suppliers or DCs. To determine this list, Streamline recalculates the Current order section based on the following lead time parameter:

Let's denote this amount as Qty to order1 for a planning item and the list, as To-replenish list.

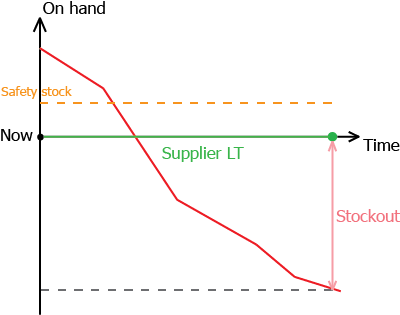

Assume we have a stockout for a planning item (see figure below).

Recall that Current order section shows orders that cover the demand during Order cycle period coming after Lead time. Therefore, such a recalculation gives us ordering quantities to cover potential stockouts (see figure below).

3. Then, two filtering procedures are applied to the To-replenish list. First, it is filtered using the Replenish-from list so that, only the items that can be replenished from the Replenish-from list are left. Then, lines having zero Qty to order1 are removed from the list.

4. After that, for each planning item in the To-replenish list a Qty to transfer is found as minimal non-zero amount from the Qty to order1 and the Stockout.

5. Then, Streamline sorts the Replenish-from list and To-replenish list in descending order by the Qty available for transfer and Qty to transfer correspondingly.

6. Finally, it goes through the sorted lists for each planning item in the Replenish-from list and generates transfers by taking lines from the To-replenish list till the remaining Qty available for transfer covers the current Qty to transfer completely.

This basic method:

In addition to that, there is an ability to add additional constraints into the basic method by introducing the regions where transfers are allowed. It is done by importing a special data type called Transfer region. Using this data type you can set up regions (sets of locations) where transfers are allowed. Transfers between regions are forbidden.

Intersite optimization tab copies the layout of the Inventory planning tab (see figure below).

This tab is designed to view and export intersite transfers. It is automatically populated with transfer recommendations generated by Streamline.

The description of the columns in the Intersite optimization tab is the same as for Inventory planning, except for the columns shown in the table below.

| Column | Description | |

|---|---|---|

| Lead time | Shows the lead time of the transfer. It is either the default intersite transfer lead time, if the planning item is sourced from a supplier; or the Lead time (from the Inventory planning tab), if it is sourced from a DC. | |

| Current order section | This section is recalculated based on the transfer lead time. | |

| Qty | Shows the quantity to transfer, which is the minimal non-zero amount from the Qty to order1 and the Stockout (from the Inventory planning tab). | |

| The other subcolumns of the Current order section show characteristics calculated for the Qty column of this section. | ||

Hyperlink in the Source from column sends you to the Inventory planning tab and sets the cursor at the planning item which is used as the source for the transfer. It is useful, for example, if want to ensure that the source location has enough On hand to fulfill the transfer.

The Settings button of the toolbar opens the Settings dialog. Options set in the Inventory tab of this dialog are applied to both Inventory planning and Intersite optimization tabs.

Description of the Intersite optimization toolbar is the same as for the Inventory planning tab.