A CFO’s Ultimate Guide to Mastering S&OP

Looking for S&OP software to streamline your business operations? Our guide offers to Chief Financial Officers a straightforward look at how these tools help match your sales planning with production capabilities to boost operational efficiency. Learn to navigate the options and select the software that best suits your needs.

Download the guide now

Key Takeaways

Traditional S&OP processes face hurdles such as reliance on error-prone spreadsheets, complexity, and analysis paralysis. Overcoming these requires modern software solutions and best practices, including securing executive ownership and fostering cross-functional collaboration.

Successful S&OP implementation hinges on factors like system compatibility, scalability, user-friendliness, and executive support. Key steps include data gathering, demand review, gap identification, and continuous plan adjustment.

Monitoring KPIs like forecast accuracy, inventory turnover, customer service levels, and supply chain cycle time is crucial for optimizing S&OP. Real-world examples, such as Unilever’s reduction in waste and enhanced capital returns, illustrate the tangible benefits of effective S&OP.

The guide reviews top S&OP software, highlighting features of Streamline, Oracle S&OP Cloud, and SAP Integrated Business Planning. These tools provide AI-powered forecasting, comprehensive planning, and advanced analytics to streamline operations and improve decision-making.

To maximize S&OP software benefits, businesses should focus on continuous improvement, executive engagement, and cross-functional collaboration. Regular audits and open communication are vital for sustained success.

Data gathering from sales and marketing teams for demand

Reviewing demand data in conjunction with supply data from operations

Identifying gaps between demand and supply

Continuous monitoring and adjustment of the plan based on real-time data

-

Agile and responsive supply chain

-

Automation of the S&OP process

More efficient process

Minimization of the risk of errors

Better business outcomes

Executive leadership

Demand planning

Supply planning

Procurement team

Finance team

Marketing team

Sales&Operations

Forecast Accuracy. Forecast accuracy measures the precision of demand forecasts compared to actual sales. Improving this KPI reduces inventory costs and enhances service levels.

Inventory Turnover. Inventory turnover indicates how often inventory is sold and replaced over a period. High turnover rates signify efficient inventory management and reduced holding costs.

Customer Service Level. Customer service level measures the ability to meet customer demand promptly. High service levels lead to increased customer satisfaction and loyalty.

Supply Chain Cycle Time. Supply chain cycle time tracks the total time from order receipt to product delivery. Reducing cycle time enhances responsiveness and reduces lead times.

Order Fulfillment Lead Time. Order fulfillment lead time measures the time taken to process and deliver customer orders. Streamlining this process improves delivery reliability and customer satisfaction.

Cash-to-Cash Cycle Time. Cash-to-cash cycle time measures the period between paying for raw materials and receiving customer payments; shortening this cycle improves cash flow and enhances working capital management.

AI-powered time series demand forecasting for highly accurate predictions

Ability to adjust to the latest market trends

Suitable for midsize and enterprise businesses

Unifying financial and operational planning

Offering advanced what-if scenario analyses, allowing companies to assess the impact of demand or supply changes and explore different strategies

Integrating different planning domains, breaking down silos and cultivating improved collaboration and efficiency in the planning process.

The software’s ability to integrate with existing systems

Its scalability and customization to cater to unique business needs

Its ease of use and implementation

Needs analysis

Installation

Integration with existing systems

Thorough testing

Attending meetings

Reviewing plans beforehand

Resolving issues around constrained shipment plans

Addressing changes that significant family plans might necessitate

- Achieve optimal 95-99%+ inventory availability, ensuring you can meet customer demand consistently.

- Attain up to 99% forecast accuracy, getting more reliable planning and decision-making.

- Experience up to a 98% reduction in stockouts, minimizing missed sales opportunities and customer dissatisfaction.

- Cut excess inventory by up to 50%, freeing up valuable capital and storage space.

- Increase margins by 1-5 percentage points, boosting overall profitability.

- Enjoy up to 56 times ROI within one year, with a 100% ROI achievable in the first three months.

- Reduce the time spent on forecasting, planning, and ordering by up to 90%, allowing your team to focus on strategic activities.

The Main Purpose of S&OP

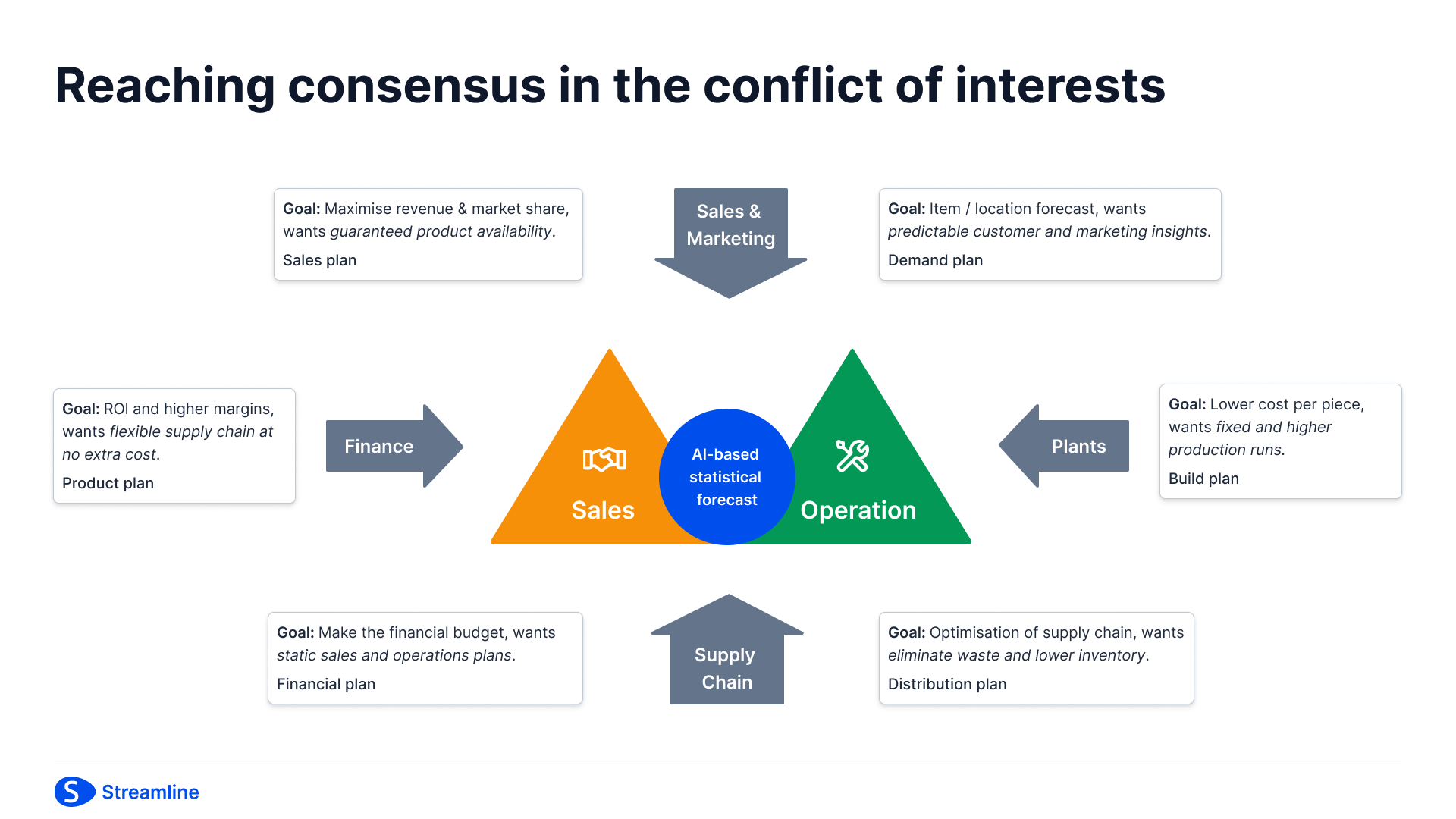

S&OP primarily aims to unite organizations around a single plan. This balance between demand and supply not only improves service levels but also reduces costs, courtesy of the operations planning S&OP process which facilitates the creation of a cohesive operations plan.

S&OP software, such as Streamline Integrated Business Planning, enables businesses to automate this process, offering a comprehensive solution for supply chain planning and supply plan management. The software provides instant insights on the supply chain disruptions, enabling efficient process and prompt decision making around the world.

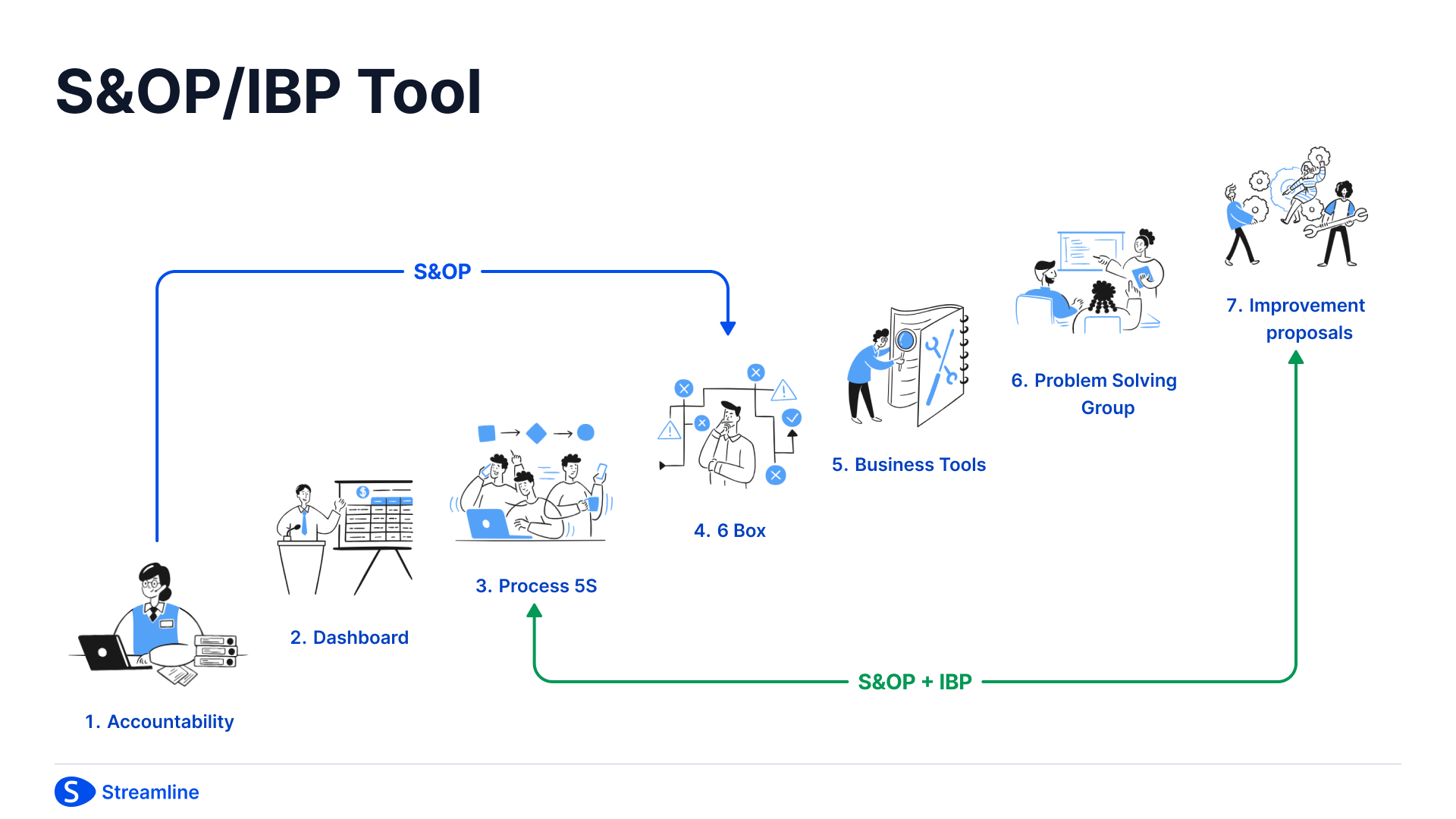

The S&OP Process

The S&OP process includes the following steps:

This process is crucial for maintaining operational efficiency and to improve customer service.

Once the gaps are identified, the next step is to develop an integrated plan to close these gaps. This is where S&OP software steps in. The software allows for:

Key Roles in S&OP

There are several key roles in S&OP that contribute to its successful implementation. These include:

These roles work in synergy to provide direction and support, gather data from sales and operations, and facilitate the overall S&OP process.

The Role of S&OP in Business Success

S&OP serves as a pivotal factor in achieving business success. It harmonizes demand, supply, and financial planning, facilitating informed decision-making and yielding superior business outcomes. It helps keep every aspect of the company on the same page, allowing for smoother functioning and a more cohesive organization.

A sales and operations plan enhances the overall customer experience by streamlining processes and ensuring all departments are aligned. The use of Sales and Operations Execution (S&OE) workflows complements S&OP processes by providing real-time planning adjustments and feedback, aligning longer-term plans with actual supply chain performance. This coordination across business units increases transparency and helps balance supply and demand, leading to profitability.

Challenges Faced in Traditional S&OP Processes

Despite its numerous advantages, the S&OP process can face some challenges. Traditional S&OP processes often rely on spreadsheets, which, while common, can be time-consuming and error-prone, making them unsuitable for scaling with business growth. Complex S&OP processes can also lead to confusion and poor stakeholder compliance, particularly for new employees who may lack understanding if ongoing education is not provided.

Another challenge is ‘analysis paralysis’, where excessive analysis leads to a lack of timely decision-making, ultimately wasting resources and reducing process value. Disagreements during the development of tactical plans are common challenges in the S&OP process, and change orders in S&OP are costly and time-intensive, placing a heavy, formal burden between users and the flexibility they need.

Key Performance Indicators (KPIs) for S&OP

By tracking KPIs, supply chain directors can gain insights into various aspects of their operations, identify areas for improvement, and make data-driven decisions to enhance overall performance. This section highlights essential KPIs for S&OP, explaining their importance and how they contribute to achieving organizational goals.

By focusing on these KPIs, organizations can drive continuous improvement, optimize their operations, and ultimately achieve a more resilient and responsive supply chain. Implementing strategies to enhance these KPIs will lead to better alignment between supply and demand, reduced costs, and higher customer satisfaction. Now, let’ds take a closer look at Technology and Tools for S&OP.

A Closer Look at Leading S&OP Software Solutions

Having discussed the fundamentals of S&OP, we will now delve into some of the pioneering S&OP software solutions that have significantly transformed the process. Streamline, Oracle S&OP Cloud, and SAP Integrated Business Planning are industry-leading solutions that offer unique features and benefits, enabling businesses to optimize their S&OP processes.

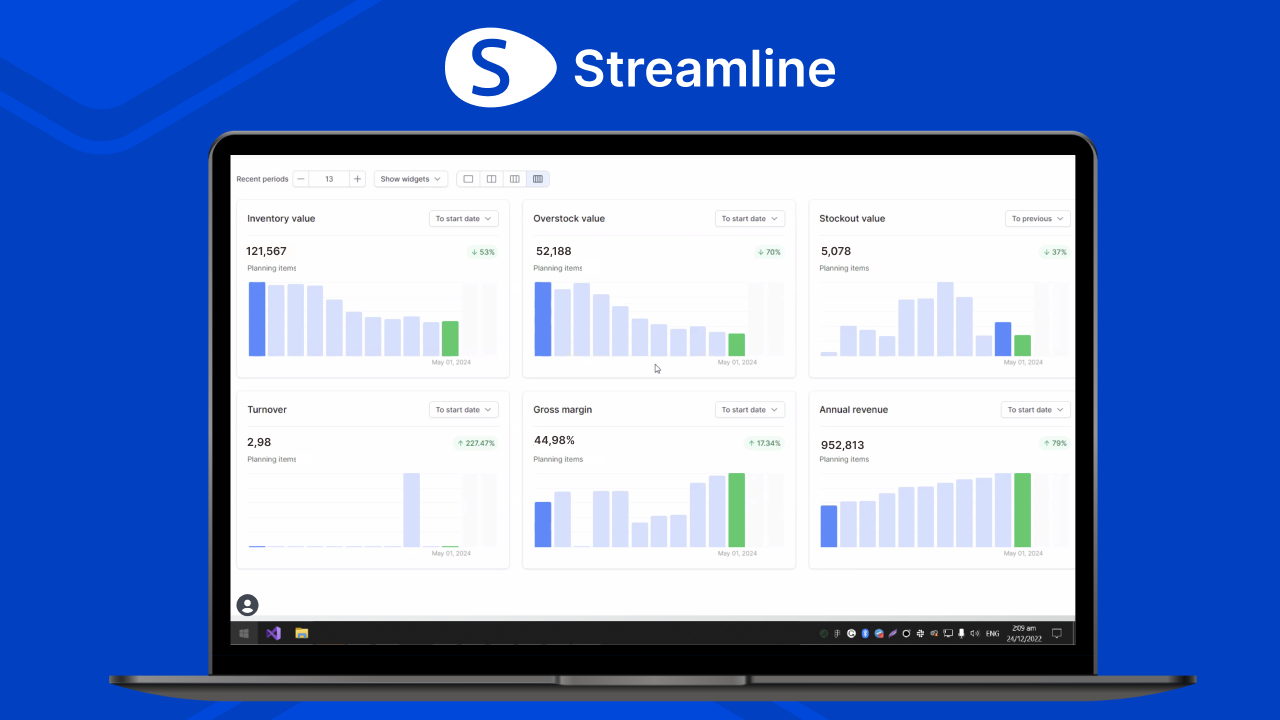

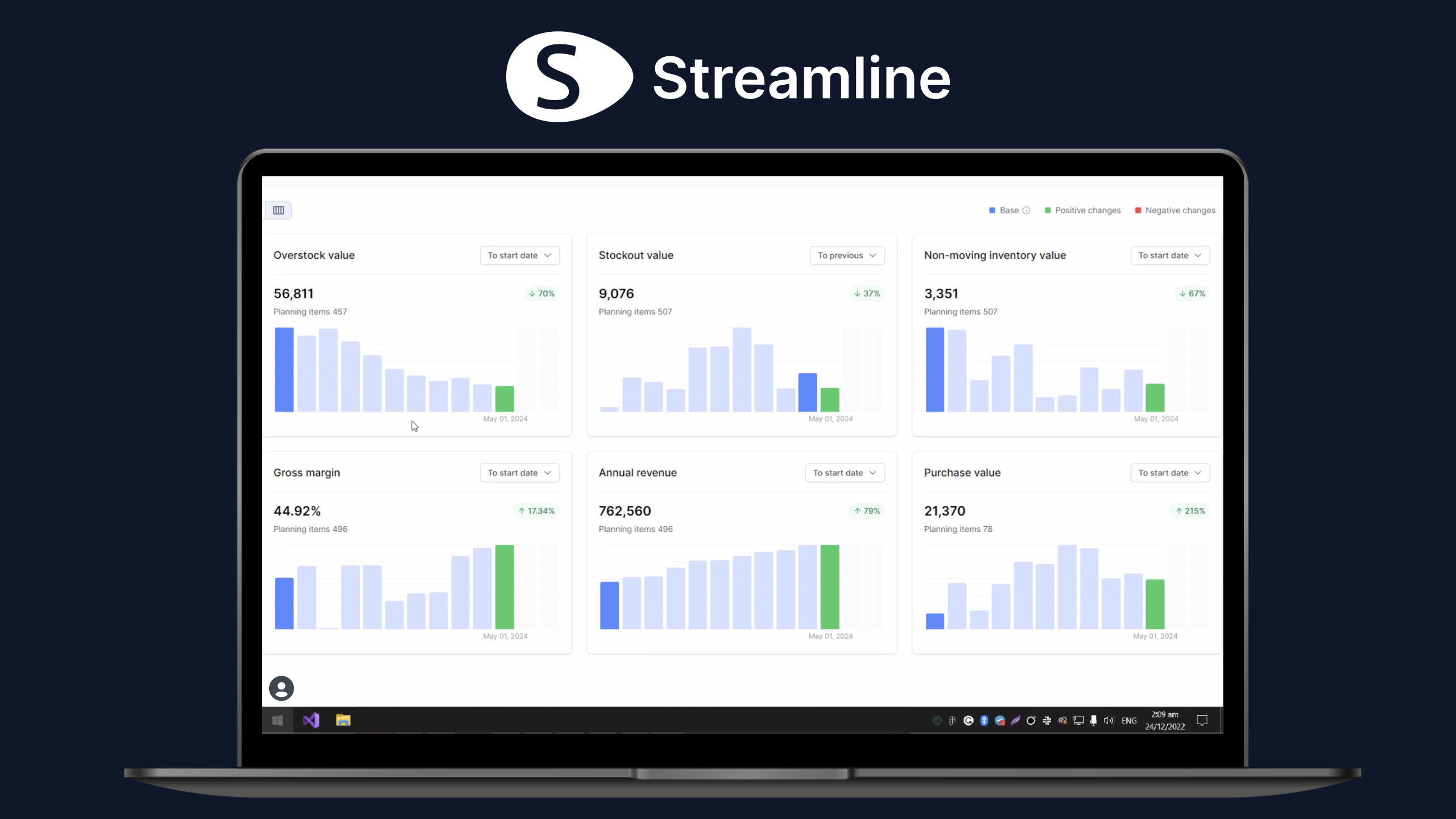

Streamline: AI-Powered S&OP Solution for Midsize and Enterprise Businesses

Tailor-made for midsize and enterprise businesses, Streamline provides a robust S&OP solution that can be deployed via cloud or on-premise. The platform offers the following features:

It enhances inventory planning by identifying risks such as overstock and out-of-stock situations, maintaining optimal inventory levels. With a clean and fast user interface, businesses can experience a smooth implementation process, contributing to Streamline’s excellent reputation in the market.

Oracle S&OP Cloud: Comprehensive Planning for Larger Businesses

Oracle S&OP Cloud supports a continuous S&OP process, connecting long-term strategy with day-to-day operations to enable the development of optimal plans. Diverse industries utilize Oracle S&OP Cloud to move towards a continuous planning approach, facilitating improved S&OP results.

The software enhances business responsiveness through its collaboration capabilities, offering a distinct advantage over traditional tools like Excel by adapting to market events such as stock-outs.

SAP Integrated Business Planning: Advanced Analytics and Scenario Planning

SAP Integrated Business Planning facilitates comprehensive planning by:

It enhances supply chain resilience through comprehensive visibility, alerting mechanisms, and analytics, empowering businesses to predict disruptions and pre-emptively address them.

Key Factors to Consider When Choosing S&OP Software

Several key factors are essential when selecting S&OP software. These include:

Integration with Existing Systems

Data integration capabilities are crucial for S&OP software, enabling centralization of master data from source systems like ERP and CRM for holistic planning. Compatibility with existing systems, including ERPs or other operational tools, is a critical consideration when selecting an S&OP software solution.

Seamless integration of S&OP software facilitates communication and information sharing across departments, which is essential for successful implementation. S&OP software equipped with embedded analytics allows users to monitor and adjust their plans based on data-driven insights for better decision-making.

Scalability and Customization

S&OP software must be adaptable to accommodate changes in business size and structure, ensuring longevity and relevance as the company evolves. Custom workflows and role-based views in S&OP software allow for a personalized approach to demand planning, increasing the tool’s efficiency for different user needs.

S&OP software that features automated production planning based on real-time data can help businesses respond quickly to market changes and scale operations accordingly.

Ease of Use and Implementation

Proper user training and ongoing support are critically important to not only smoothly implement S&OP software but to make sure it is effectively utilized by the team. The successful deployment of S&OP software is assured by a comprehensive process that includes:

A straightforward and intuitive software interface greatly reduces the learning curve for users and encourages broader adoption within the organization.

Real-World Examples: Success Stories with S&OP Software

To grasp the effects of S&OP software, we will explore a few real-world examples. Unilever, for instance, implemented an S&OP process that led to a 20% reduction in waste across its supply chain and a 6% increase in return on invested capital.

How Streamline enhanced supply chain visibility for one of the most important pet segment retailers in the LATAM region

Streamline has had a significant impact on inventory management and sales forecast. Its integration with external data sources has enhanced the accuracy of demand forecasting, leading to more reliable supply plans and better business decisions.

As a direct result of more accurate forecasting, companies using Streamline experienced optimized inventory levels, avoiding both overstock and stockouts.

Best Practices for Implementing and Optimizing S&OP Software

Adhering to certain best practices is essential to maximize the benefits of your S&OP software. These include securing executive ownership and support, fostering cross-functional engagement, and investing in continuous improvement and adaptation.

Executive Ownership and Support

Executive ownership and backing are fundamental to the successful deployment of S&OP software. Executives must take ownership and effectively arbitrate conflicts between sales and operations. During the monthly S&OP cycle, active participation from executives is essential, which includes:

Executives are also expected to stand behind the S&OP plan, especially when communicating with corporate stakeholders.

Cross-Functional Engagement

Another vital element for effectively implementing S&OP software is cross-functional engagement. Establishing common goals and shared metrics across departments fosters collaboration and aligns efforts. Defining roles and responsibilities for each team member within the S&OP process promotes accountability and streamlines communication.

Encouraging open dialogue and feedback among different departments achieves consensus and fosters collaboration in the S&OP process. Celebrating and rewarding success within the S&OP team motivates members, promotes a positive culture, and reinforces the value of collaboration.

Continuous Improvement and Adaptation

The success of S&OP software implementation heavily relies on ongoing improvement and adaptation. Regular evaluation of S&OP ensures its effectiveness and allows for adjustments in response to market conditions and business needs. A clear infrastructure representing the various enterprise stakeholders in S&OP is crucial for maintaining high levels of engagement and driving ongoing process improvement.

Periodic internal audits of S&OP process operation can identify key strengths and highlight areas for improvement, but must be set up to focus on continuous improvement rather than just policing adherence.

Summary

In conclusion, S&OP is a powerful tool that can transform the way businesses operate. By aligning demand and supply, improving service levels, and reducing costs, it can significantly enhance performance. While the process may have its challenges, implementing S&OP software can help overcome these hurdles. Streamline, Oracle S&OP Cloud, and SAP Integrated Business Planning are industry-leading solutions that offer unique features and benefits, enabling businesses to optimize their S&OP processes. By considering factors like integration with existing systems, scalability, customization, and ease of use, businesses can select the right S&OP software to fit their needs.

Download the guide now

Frequently Asked Questions

What is the difference between S&OP and MRP?

The main difference between S&OP and MRP lies in their approach to managing shipment plans and supply plans. While S&OP focuses on matching inventory, MRP prioritizes planning the supply to meet requirements. Ultimately, the difference is that S&OP emphasizes inventory, whereas MRP emphasizes supply.

What company uses S&OP?

Carters, a leading retailer of young children’s apparel in the United States and Canada, uses S&OP to solve supply chain issues. This implementation allowed Carters to remove inventory from its supply chain, improving efficiency.

What is a S&OP system?

A S&OP system, or sales and operations planning system, is an integrated process aligning demand, supply, and financial planning to drive organizational consensus for balancing supply and demand in business operations.

How do you do sales and operations planning?

To do sales and operations planning, follow a six-step process: gather and forecast data, review demand, plan production, reconcile plans in a pre-S&OP meeting, finalize in an executive meeting, and implement the strategy. This process involves collecting data, reviewing demand, planning production, reconciling plans, finalizing in an executive meeting, and implementing the strategy.

What is the purpose of S&OP?

The purpose of S&OP is to align organizations around a single plan, balance demand and supply, and improve service levels while reducing costs. S&OP helps in achieving operational efficiency and meeting customer demands effectively.

Still relining on manual work in Excel for sales and operations planning (S&OP)?

See what Streamline can do for you

Still relying on manual work in Excel for planning?

Automate demand and supply planning with Streamline today!

- Achieve optimal 95-99%+ inventory availability, ensuring you can meet customer demand consistently.

- Attain up to 99% forecast accuracy, getting more reliable planning and decision-making.

- Experience up to a 98% reduction in stockouts, minimizing missed sales opportunities and customer dissatisfaction.

- Cut excess inventory by up to 50%, freeing up valuable capital and storage space.

- Increase margins by 1-5 percentage points, boosting overall profitability.

- Enjoy up to 56 times ROI within one year, with a 100% ROI achievable in the first three months.

- Reduce the time spent on forecasting, planning, and ordering by up to 90%, allowing your team to focus on strategic activities.