The Best AI-Driven Cin7 Inventory Planning Software to Achieve 99%+ Availability without Overstocking in 2025

01. Streamline 👈 our favorite platform

Price: The free edition is free forever

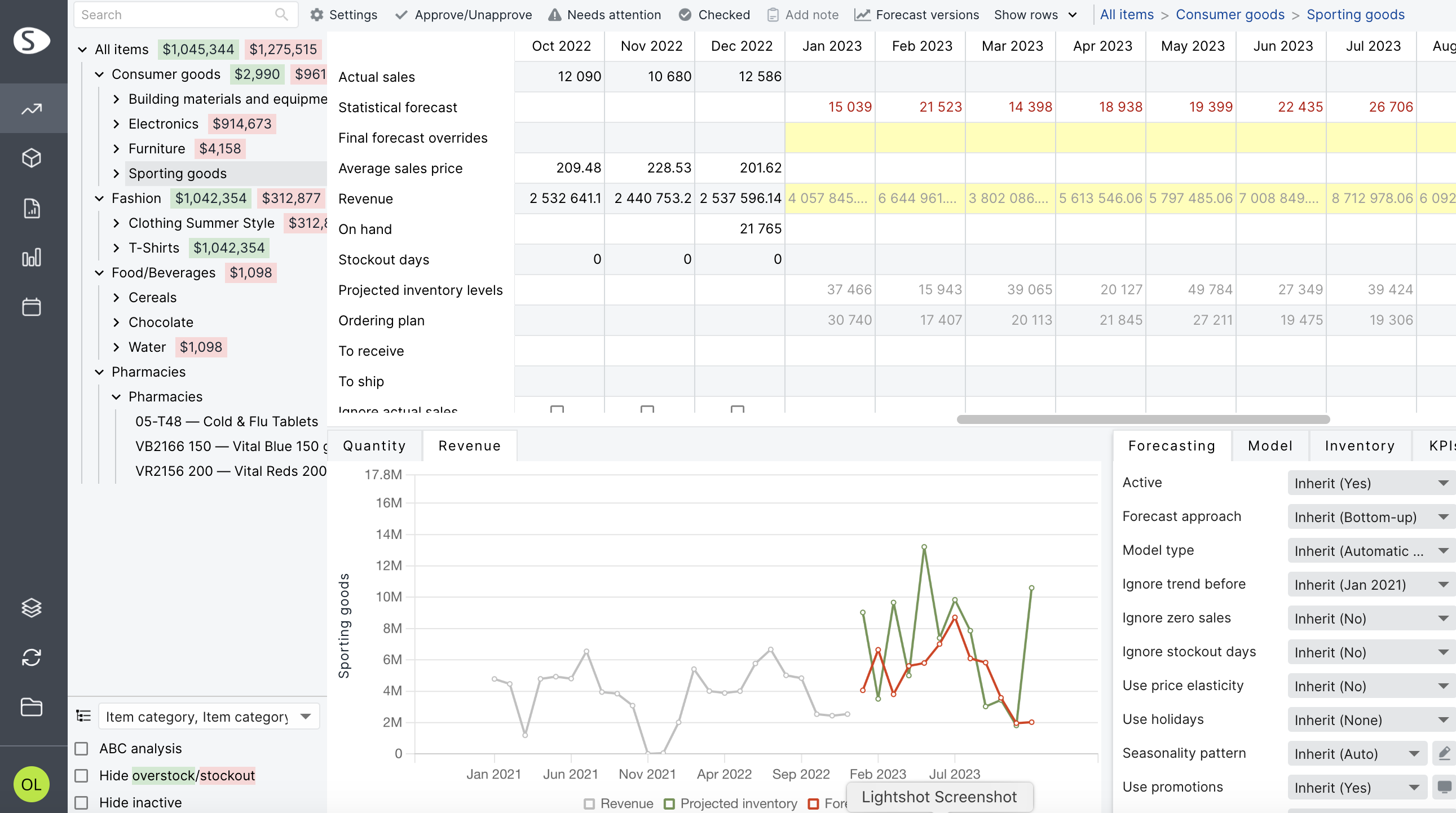

Overview: Streamline is the industry-leading Cin7 Inventory Planning Software Platform for fast-growing enterprises.

Headquartered in New York, Streamline has over 200 implementation partners worldwide and thousands of enterprise customers who rely on its AI-powered platform to accurately forecast demand and optimize inventory. The platform helps fast-growing manufacturers, retailers, wholesalers, and distributors to operate more efficiently, reducing costs and increasing profits.

Pros:

- Enterprise-grade platform

- Multi-echelon planning

- Integrated Business Planning (IBP)

- A wide range of advanced features and customizations

- Quick implementation time

- Multiple ERP integrations

- 99%+ inventory availability

- AI-driven demand forecasting

- Out-of-stock reduction by up to 98%

- Excess inventory reduction by up to 50%

- Planning time optimization by up to 90li>

- Best long-term ROI

Cons: Some features require user training

Platform: Web-based

Deployment options: Cloud or on-premise

Market Segment: Enterprise

“If you are using Excel spreadsheets for Demand & Supply planning, move quickly to this software that will certainly make your planning much more efficient, capitalize benefits very fast, and make your life much easier.”

Inventory planning is a business process aimed to determine the optimal quantity and timing of inventory for the purpose of integration production capacity and sales. Inventory planning hugely influences a company’s turnover, cash flow, and profit margins.

Benefits of the Streamline’s Cin7 inventory planning solution:

1. Fast and intuitive user interface

Streamline software is both efficient and effective, allowing you to focus on long-term goals and business growth.

2. Seamless integration of company data sources

Bidirectional connectivity enables data import from your sales system into Streamline and allows for automatic export of forecasted order information back to your ERP system.

3. Smooth and fast implementation process

Successful implementation requires coordination of various factors. The Streamline team is well-versed in the diverse sales and ERP systems available today, ensuring your team is fully prepared for a smooth go-live.

4. Aligned with your business processes

Cin7 Inventory Planning Software should align with your business goals and processes. Factors to consider when selecting a system include total cost of ownership, reliability, quality of support, and the ability to evaluate all features before making a decision.

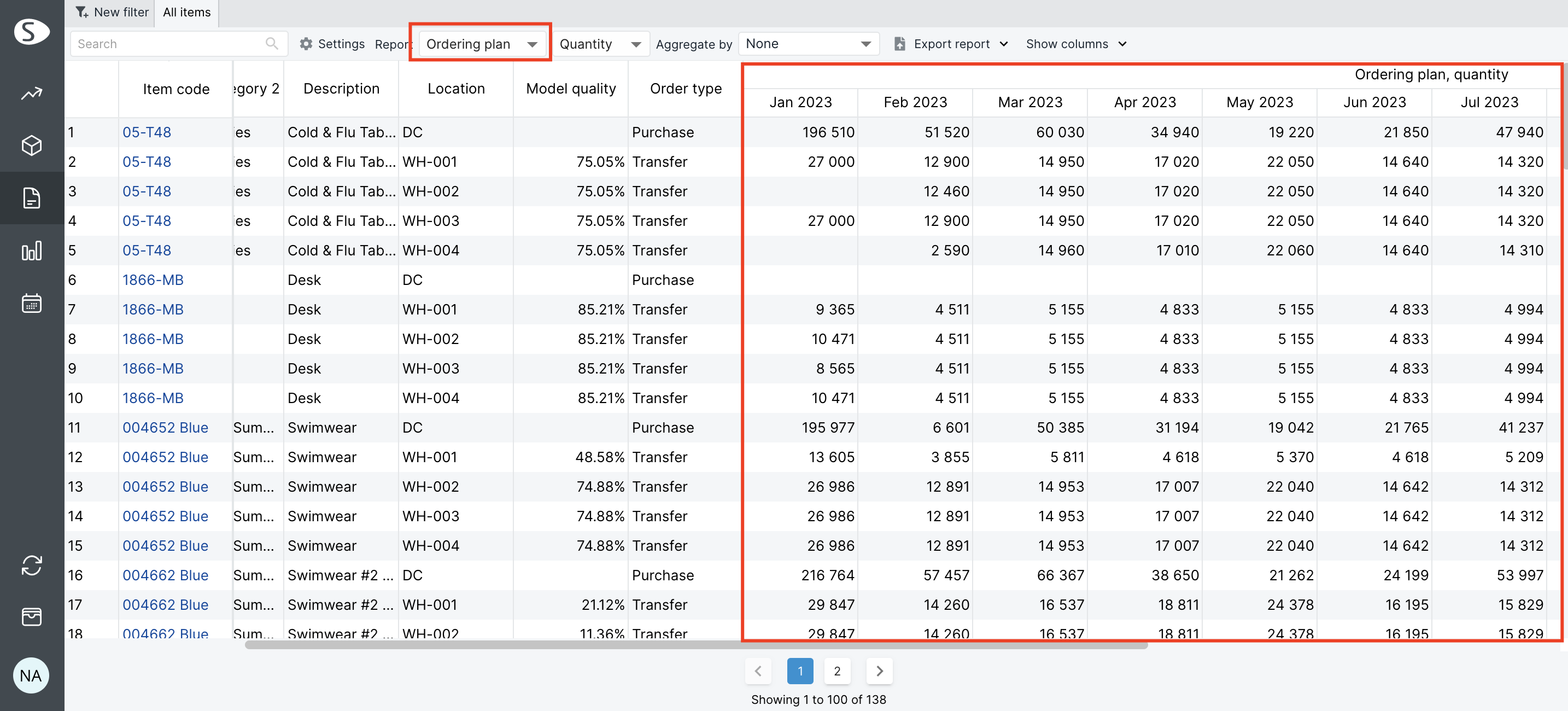

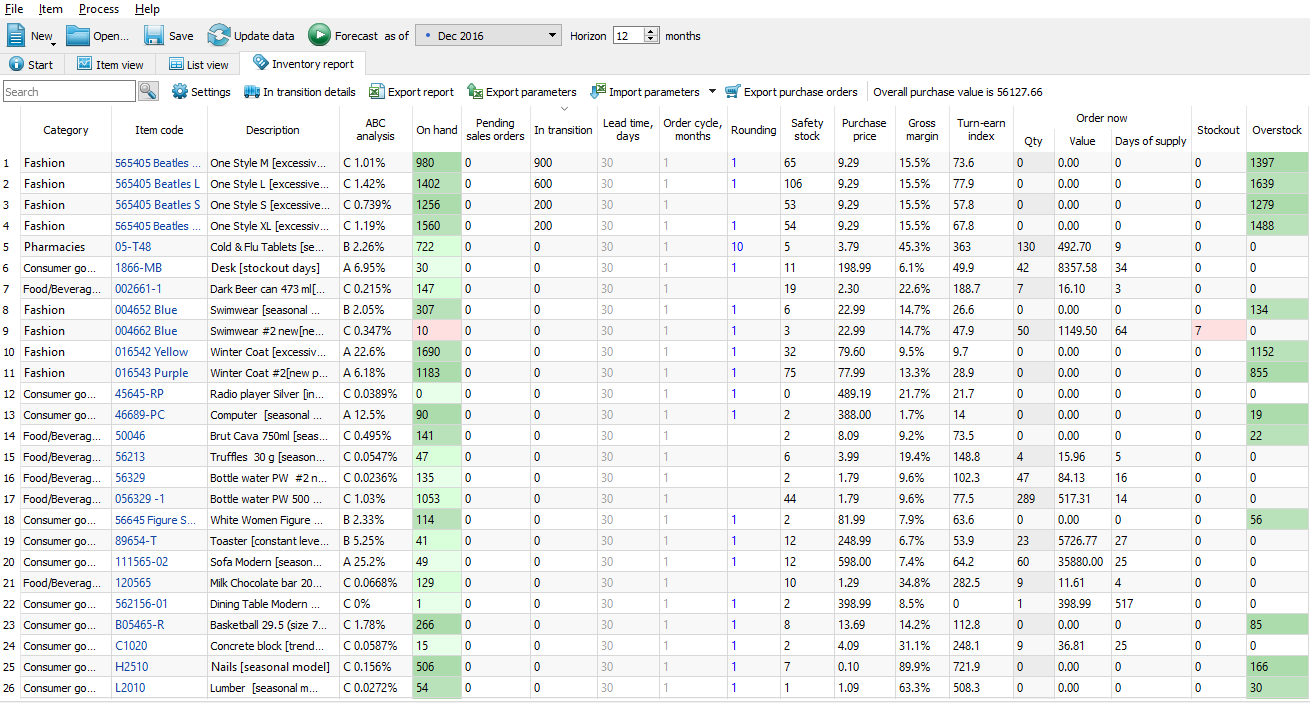

5. Syncing ordering dates across SKUs

What do you do if your Min/Max replenishment strategy built-in into the ERP system throws a purchasing signal for one SKU, but other SKUs of the same supplier do not need replenishment yet? Min/Max ordering signals come per item while businesses issue purchase orders per supplier. So you either ignore the alert and have a shortage later or purchase a full container excessively. As opposed to ERP methods, Streamline raises purchasing signals per supplier. Streamline software predicts all purchasing signals during the next order cycle via a discrete-event simulation and purchases beforehand to have a smooth purchasing process with constant order cycle, or purchasing full containers (order cycle is variable), or EOQ.

6. Replacing spreadsheets formulas with discrete-event simulation

Streamline uses discrete-event simulation instead of static formulas, building a one-day resolution timeline to model real-world inventory flows. This enables more accurate planning and accommodates complex supply chain scenarios that Excel simply can’t handle.

While our other solutions usually simplify calculations without colliding events realistically, Streamline creates a timeline with a one-day resolution and puts all schedules onto the timeline. Then Streamline executes the event sequence giving us the most accurate information about the company’s inventory levels with one-day precision. Sometimes it’s just a more precise method compared to replenishment formulas, but in many cases, it’s the only way to accommodate for the real-world supply chain complexity.

7. AI-powered demand forecasting

Estimating seasonality, price elasticity, or top-down forecasting is not enough nowadays. Market changes very dynamically, and it’s hard to predict if your history of sales is yet relevant enough to the current situation and can be used to extrapolate into the future. That’s an area where we use our proprietary AI, so we only apply time series forecasting techniques, predictors, and level changes if AI says it’s appropriate to apply – just like if you are keeping an eye on every SKU every day.

8. Group EOQ (Economic order quantity) optimization

Are you using EOQ in your work? If not, it is worth giving EOQ a closer look as this inventory planning concept significantly reduces your holding and ordering costs. Unfortunately, classic EOQ is calculated per SKU and not a group of SKUs. In a real-world supply chain, purchase orders contain several SKUs, if not hundreds. While Streamline supports classic EOQ calculation, it also offers group EOQ that goes far beyond the traditional approach making EOQ applicable to purchase orders with groups of SKUs.

That becomes possible thanks to the ability of Streamline to sync the order date for a group of items. Then Streamline moves the synchronization barrier back and forth to find the best order cycle for the group of SKUs and automatically minimizes the combination of holding and ordering costs.

Price: Request Streamline pricing.

Demo: Get a demo.

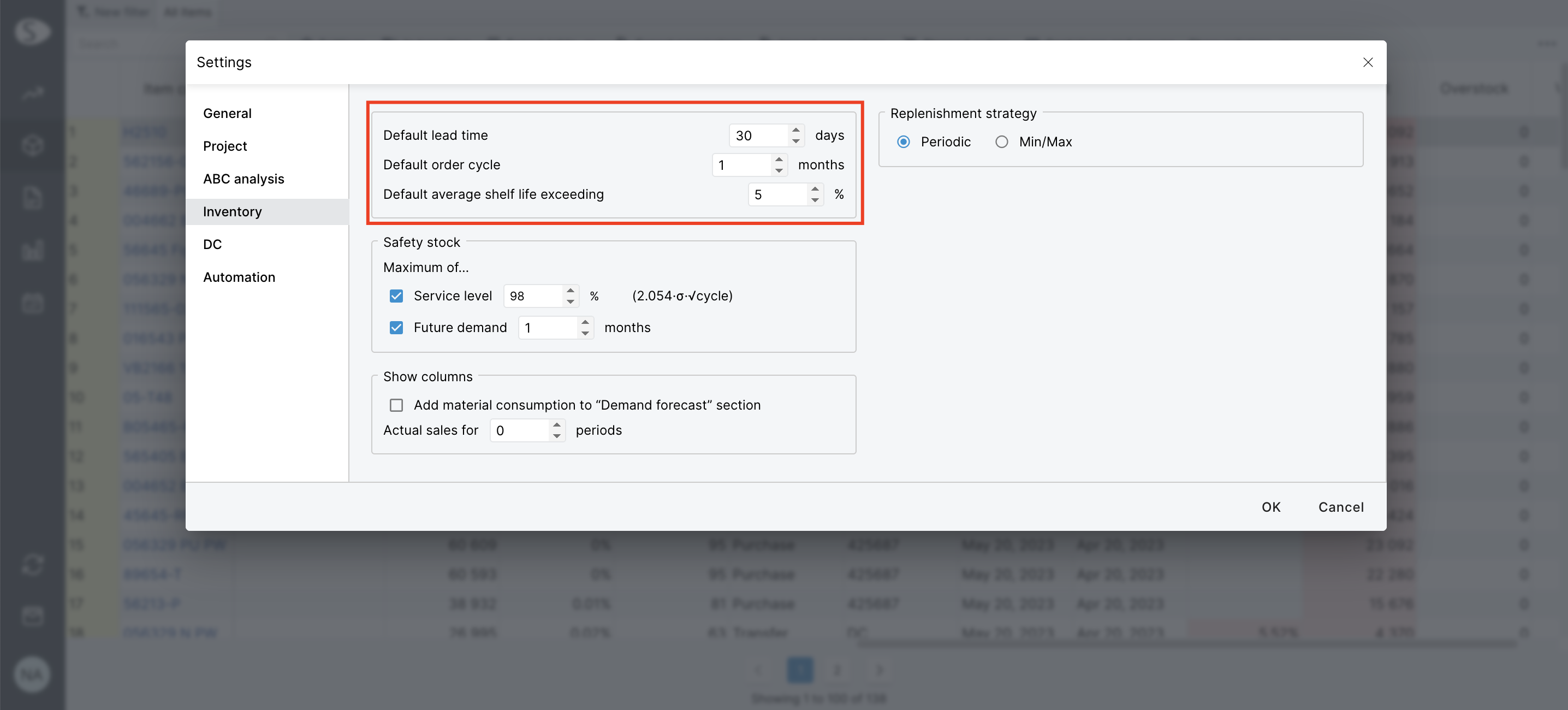

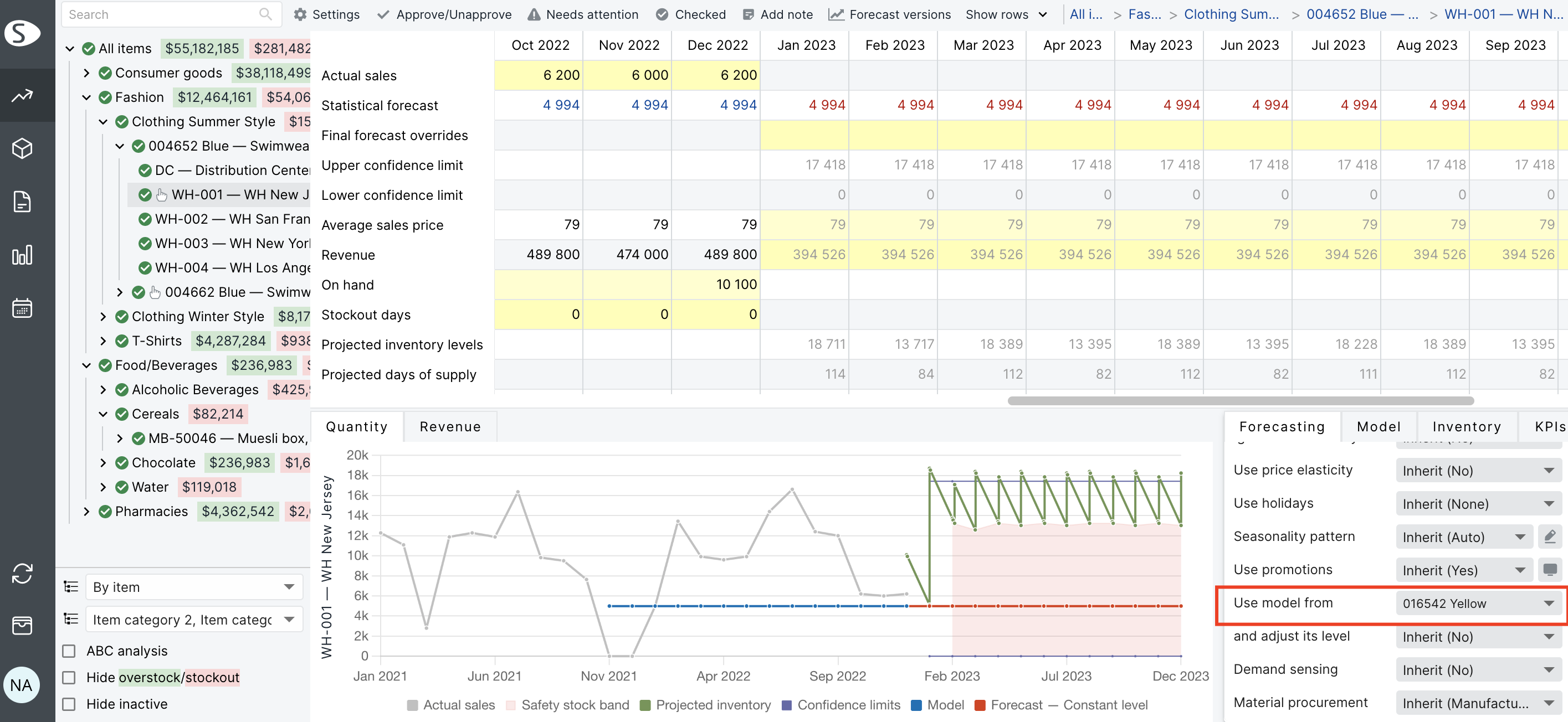

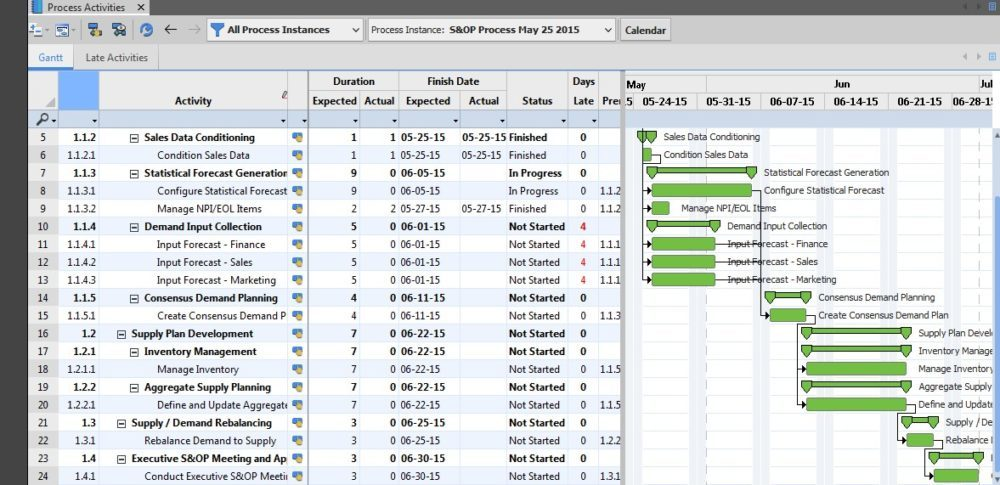

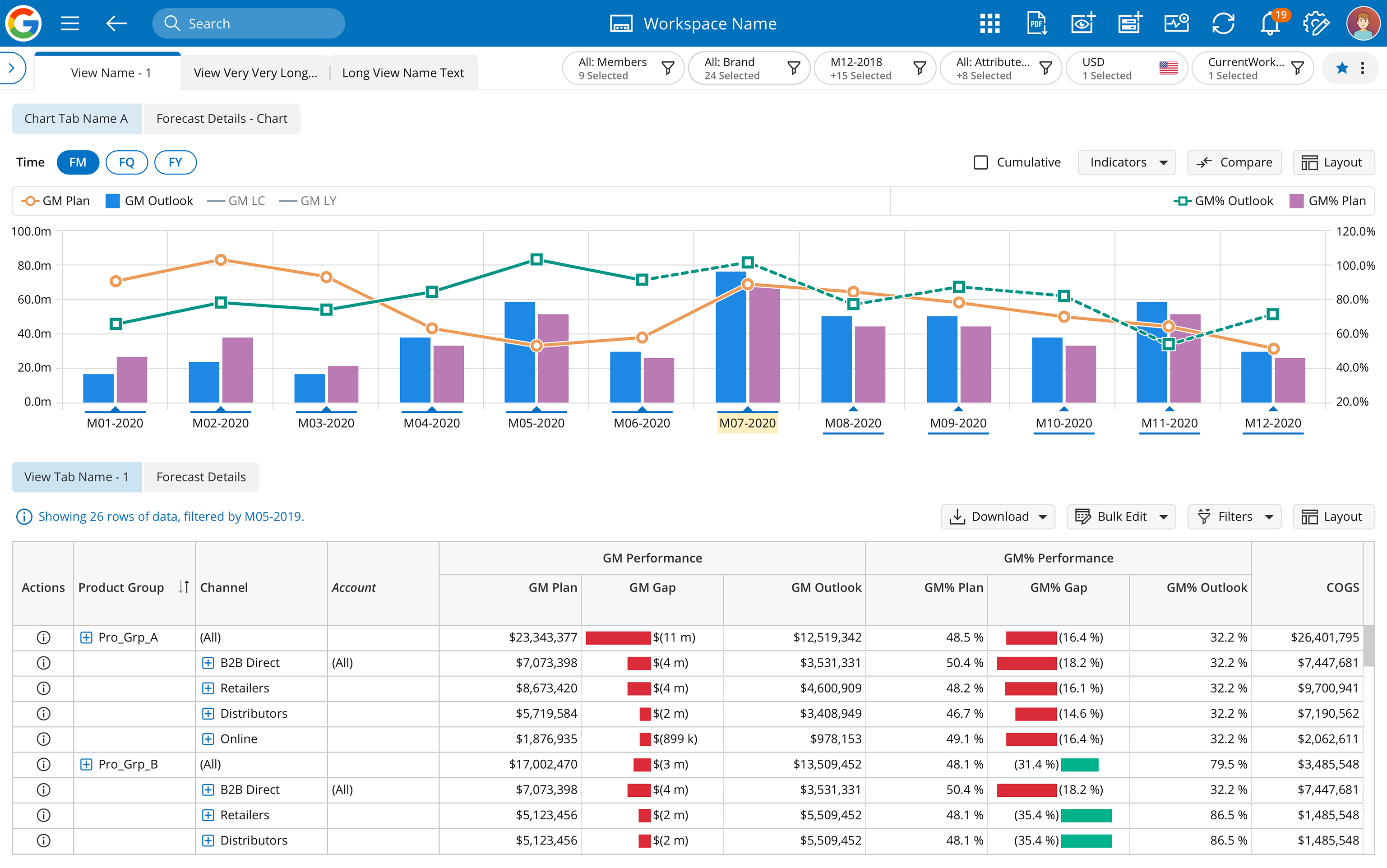

Inventory planning in Streamline

Let us take a closer look at Streamline features specific to inventory planning:

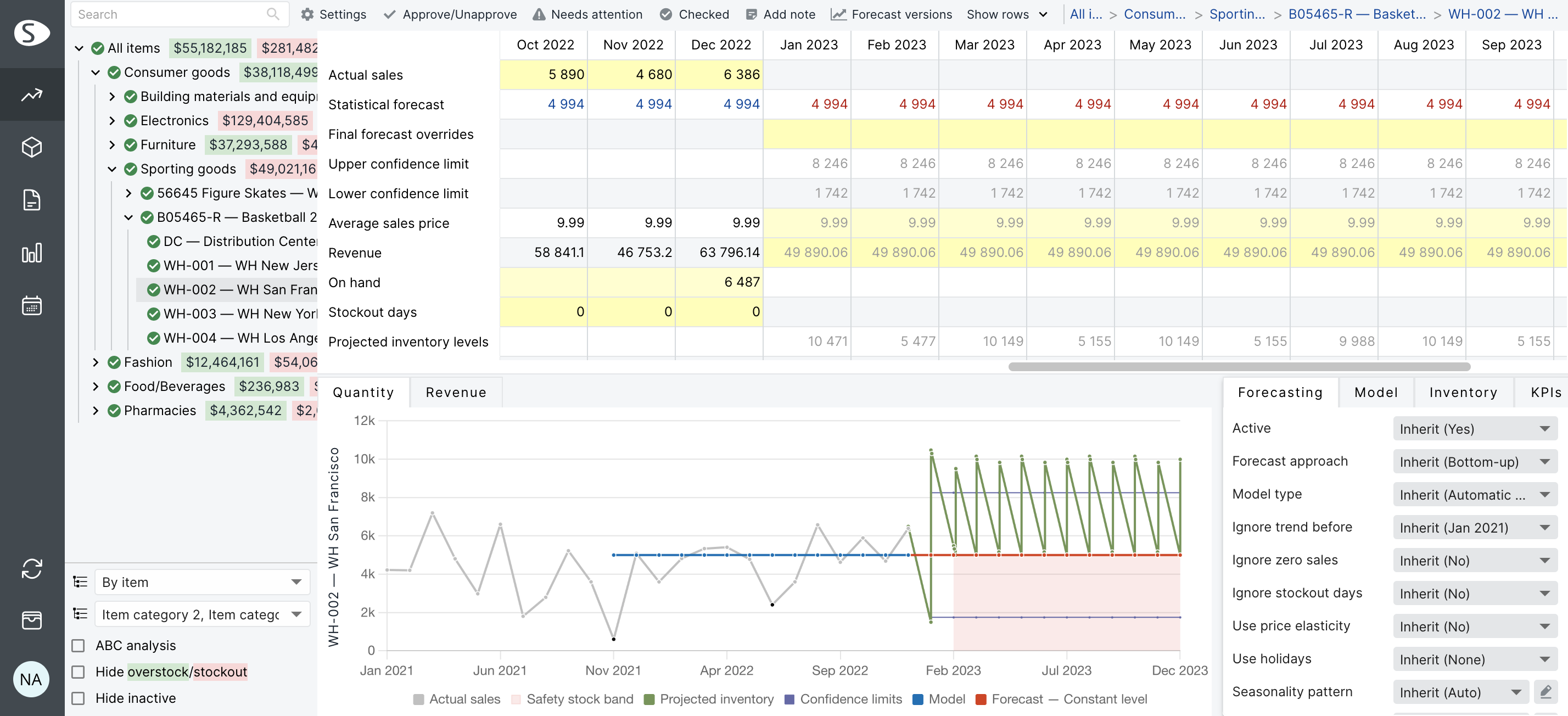

- Accurate Demand Forecast

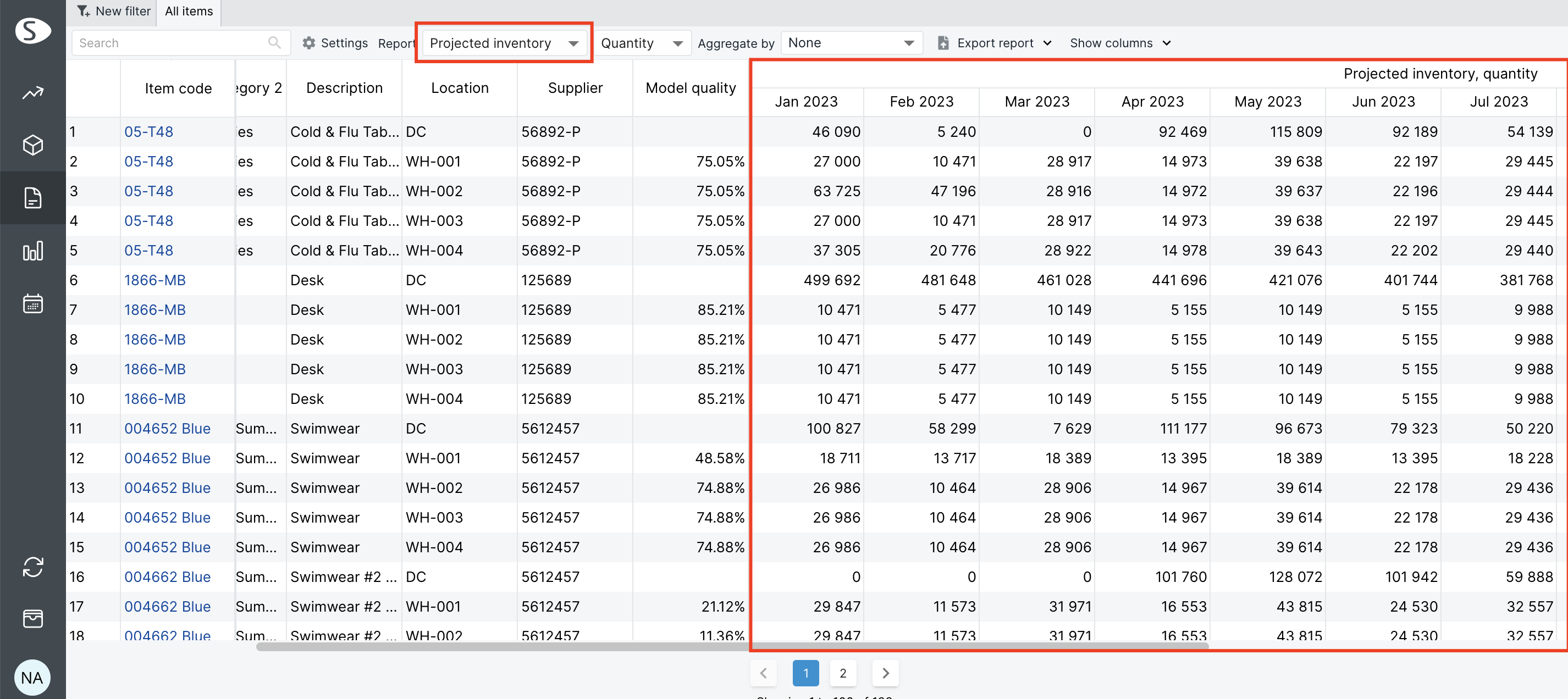

- Projected Inventory Levels

- Order Planning

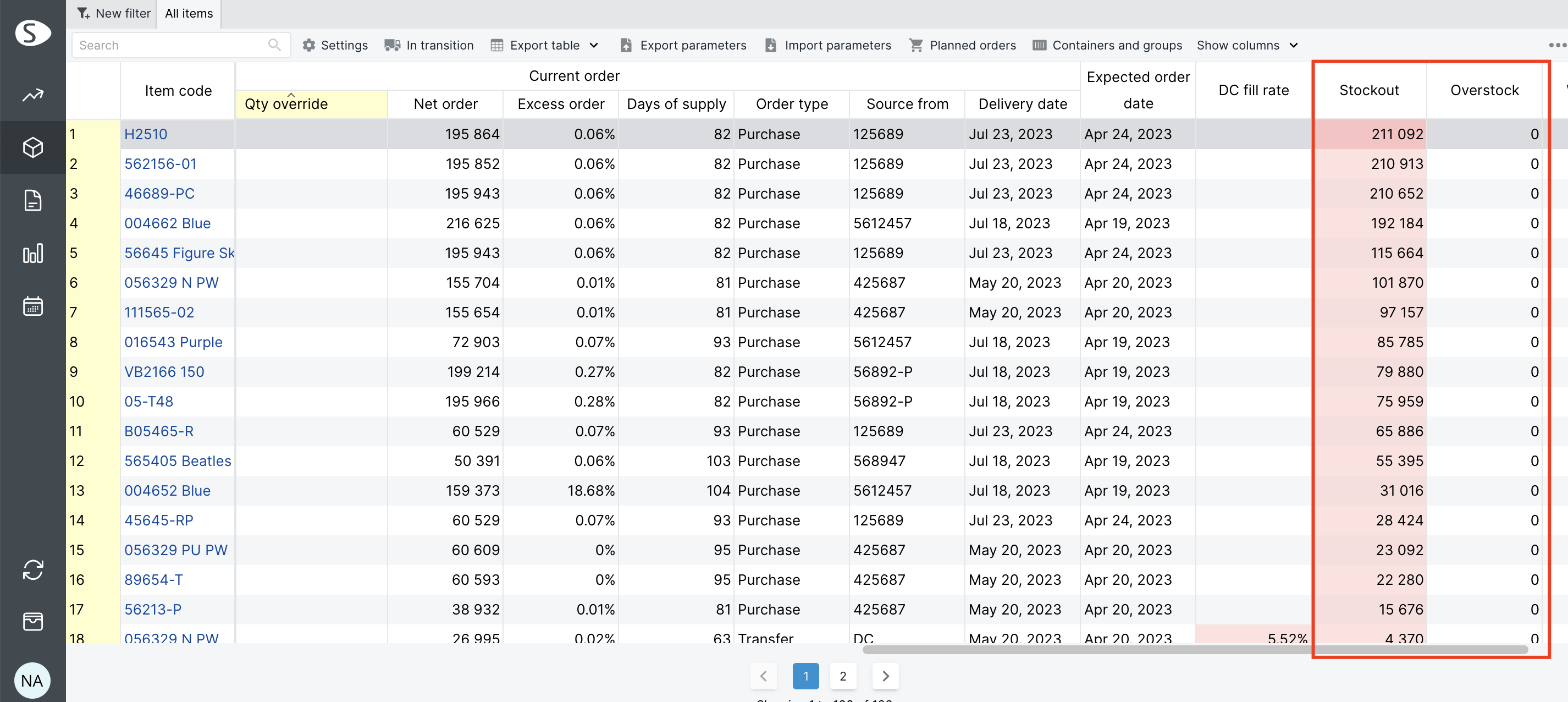

- Stockout/Overstock alerts

- Inventory Optimization

Get a demo with Streamline experts to see how you can improve the inventory planning process in your company.

Still relying on manual work in Excel for planning?

Automate demand and supply planning with Streamline today!

- Achieve optimal 95-99%+ inventory availability, ensuring you can meet customer demand consistently.

- Attain up to 99% forecast accuracy, getting more reliable planning and decision-making.

- Experience up to a 98% reduction in stockouts, minimizing missed sales opportunities and customer dissatisfaction.

- Cut excess inventory by up to 50%, freeing up valuable capital and storage space.

- Increase margins by 1-5 percentage points, boosting overall profitability.

- Enjoy up to 56 times ROI within one year, with a 100% ROI achievable in the first three months.

- Reduce the time spent on forecasting, planning, and ordering by up to 90%, allowing your team to focus on strategic activities.

Watch the inventory planning capabilities video

See the key features and benefits of the Streamline platform in action.

Global HQ

| 55 Broadway, 28th floor |

| New York, NY 10006, USA |