Streamline maximizes profits with EOQ

–

Table of Contents:

- 1. What is EOQ?

- 2. What is unique about EOQ in Streamline?

- 3. What is the best period of purchasing?

- 4. When does the EOQ replenishment strategy, or group EOQ, create additional value?

- 5. Summary

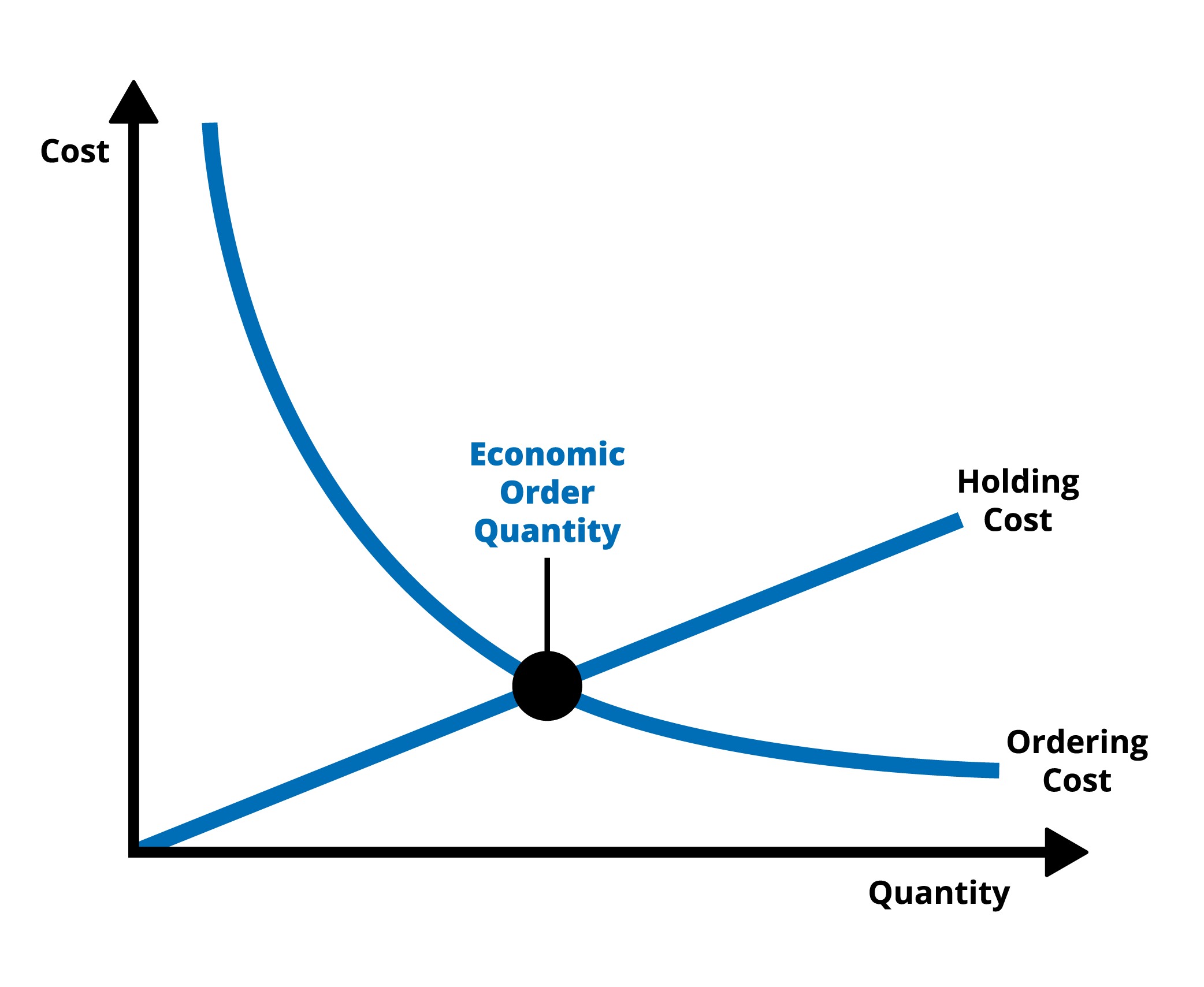

Are you using EOQ in your work? If not, it is worth giving EOQ a closer look as this inventory planning concept reduces your holding and ordering costs significantly. And if you do use EOQ, let’s see how to address common issues of EOQ for seasonal products and aggregate EOQ for a group of products.

What is EOQ?

EOQ – Economic Order Quantity is a replenishment method that increases profitability of inventory turnover. Profits are basically what we earn less what we spend, so EOQ gives us the minimum of inventory holding and ordering (or transportation) costs. Of course, EOQ depends also on product seasonality and it can be significantly higher during the high period.

What is unique about EOQ in Streamline?

Unfortunately, classic EOQ is calculated per SKU, and not a group of SKUs. That means you can only use it for moving goods from your distribution center to your own stores/warehouses because you are free to move any particular item at any time.

In real-world supply chain purchase orders you are sending to suppliers contain a number of SKUs, if not hundreds. Also the orders are often issued based on container size and do not tolerate reorder signals of different SKUs popping out at a random time.

Solution to this issue comes from Streamline’s ability to sync reorder points of any group of SKUs, for example, based on supplier, or based on what SKUs can travel in the same container.

Streamline questions the period of purchasing and changes your order cycle.

What is the best period of purchasing then?

Purchasing monthly or biweekly may not result in the lowest holding and ordering costs. So Streamline moves the barrier of synchronization back and forth to find the best order cycle for the current order that minimizes the combination of costs like EOQ, but for a group of SKUs purchased at a time.

When does the EOQ replenishment strategy, or group EOQ, create additional value?

1. Classic EOQ works best peplacing the Min/Max strategy usually applicable when a distribution center supplies stores.

2. Group EOQ is applicable even for purchase orders usually rounded to a container size. For inexpensive products EOQ will select the right number of containers or the right container size, if there’s no need to pay for a large container based on the demand projections. But for expensive products, EOQ can be less than one container that reduces holding costs and frozen capital without reducing service levels.

Summary

To conclude, Streamline supports classic EOQ calculation optimizing transfer orders between a distribution center and stores. But, it also offers group EOQ that goes far beyond that, making the EOQ application possible for purchase orders containing groups of SKUs or suppliers.

Still relying on manual work in Excel for planning?

Automate demand and supply planning with Streamline today!

- Achieve optimal 95-99%+ inventory availability, ensuring you can meet customer demand consistently.

- Attain up to 99% forecast accuracy, getting more reliable planning and decision-making.

- Experience up to a 98% reduction in stockouts, minimizing missed sales opportunities and customer dissatisfaction.

- Cut excess inventory by up to 50%, freeing up valuable capital and storage space.

- Increase margins by 1-5 percentage points, boosting overall profitability.

- Enjoy up to 56 times ROI within one year, with a 100% ROI achievable in the first three months.

- Reduce the time spent on forecasting, planning, and ordering by up to 90%, allowing your team to focus on strategic activities.