How Streamline reduced stockouts by 50% for automotive manufacturer

About the company

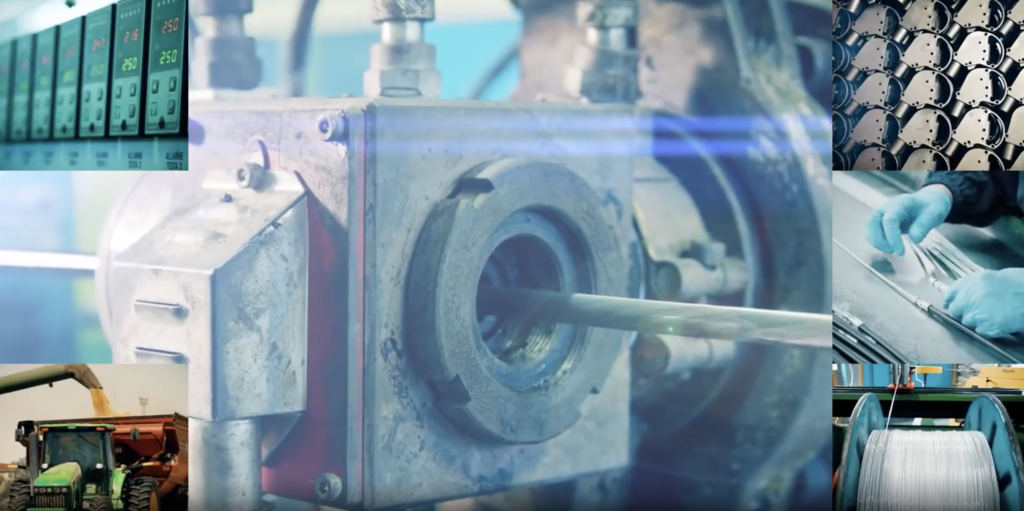

Cofle is a global automotive industry company, selling cables and systems with a widespread presence across 6 countries, operating through 6 state-of-the-art production sites, highly efficient logistic centers, and a dedicated design and co-engineering project department. With a team of over 550 skilled professionals, Cofle is committed to delivering excellence in its products and services. The extensive Aftermarket Catalogue offers over 7,000 solutions, meticulously crafted and developed utilizing OEM expertise and designed to meet OEM technical specifications.

Challenge

Cofle faced several challenges in its industry, primarily related to optimizing time spent on forecasting and inventory analysis, reducing stockouts, forecasting new products, and the vulnerability to respond quickly to market changes.

Project

As part of the implementation process, the Cofle team underwent comprehensive training to utilize the product effectively. Through this training, they successfully transitioned from manual management of demand and purchase planning using Excel sheets to a streamlined system. The user-friendly interface of the system made the adoption process seamless and intuitive, ensuring a smooth transition for the team. Cofle was equipped with comprehensive learning materials and received ongoing support, ensuring a smooth and comprehensible implementation process.

Outcomes

Since implementing Streamline, Cofle has experienced significant positive outcomes. One key achievement is the optimization of the planning process, resulting in time savings and a nearly 50% reduction in stockouts. The Stockholm Tele metric, which measures the percentage of products with low stock levels, has improved from 11.5% to 4.5%. Additionally, the challenge of accurately forecasting new products has been successfully addressed. These advancements have had a tangible impact on Cofle’s operational efficiency.

“The best thing is that Streamline is making us save plenty of time when it comes to checking inventories, and stockouts, previously managed by using Excel spreadsheets. And the great result is that since we implemented Streamline, we managed to break down by more than half the stock-out items,” – said Filippo Barbieri Tavecchio, AM Logistics supervisor at Cofle.

Do you want to test Streamline on your company’s data?

Further Reading:

- How to deal with supply chain processes during the Coronavirus outbreak

- Why switch from Excel to inventory planning software

- Must-read: Smart Supply Chain Management solutions for business processes optimization

- Cross-Functional Alignment in Supply Chain Planning: A Case Study of Sales and Operations Planning [PDF]

- Demand & Supply Management: Collaborative Planning, Forecasting & Replenishment

Still relying on manual work in Excel for planning?

Automate demand and supply planning with Streamline today!

- Achieve optimal 95-99%+ inventory availability, ensuring you can meet customer demand consistently.

- Attain up to 99% forecast accuracy, getting more reliable planning and decision-making.

- Experience up to a 98% reduction in stockouts, minimizing missed sales opportunities and customer dissatisfaction.

- Cut excess inventory by up to 50%, freeing up valuable capital and storage space.

- Increase margins by 1-5 percentage points, boosting overall profitability.

- Enjoy up to 56 times ROI within one year, with a 100% ROI achievable in the first three months.

- Reduce the time spent on forecasting, planning, and ordering by up to 90%, allowing your team to focus on strategic activities.