How does Digital Transformation work for the Supply Chain Strategy?

In the fast-paced business world today, it’s crucial for companies to use digital technology in their supply chain strategies. With industries evolving rapidly, undergoing digital transformation becomes essential to stay competitive, improve operations, and ensure customer satisfaction.

In this webinar, our expert speakers Akarat R., Managing Director at Inno Insight Co., Streamline Strategic Partner, Alan Chan, Transformation Strategist at i4SBNZ Advisors, Streamline Strategic Partner and Lu Shi, Supply Chain & Procurement Professional, Product Expert at Streamline took a closer look at how digital changes spark new ideas in supply chain plans, explore key principles, creating a roadmap and framework, defining success in S&OP.

What is the significance of Digital Transformation?

Digital transformation means changing how a company works at its core. The goal of a digital transformation should be to build competitive advantage by continuously deploying technology.

“Speaking about digital transformation, we can pay attention to four key steps: reworking organizational operations, shedding outdated practices to gain a competitive advantage, deploying technology on a large scale, and improving customer experiences while reducing costs,” – said Alan Chan, Transformation Strategist at i4SBNZ Advisors.“The digital transformation is a comprehensive and strategic process, not a quick fix.”

Building a Roadmap to overcome the challenges

The roadmap addresses uncertainties, challenges, and key drivers, including political, environmental, economic, social, ethical, legal, and technological factors. The speakers highlighted the importance of a roadmap for long-term business growth supported by ongoing changes to business and supply chain models.

Seven critical elements for overcoming short and long-term challenges were outlined: business and supply chain strategy growth, risk mitigation, supply chain optimization, cross-functional collaboration, data-driven decision-making, advanced analytics, and adaptability with risk-taking.

Creating a Roadmap

Here is a step-by-step process for creating an effective digital supply chain roadmap.

- 1. Identify Supply Chain’s Objectives for Supporting Digital Optimisation and Transformation

- 2. Determine Changes in Supply Chain’s Capabilities and Processes

- 3. Prioritize Investments in Technology

- 4. Create a Plan to Address Supply Chain’s Digital Talent Gaps

- 5. Determine a Governance Framework and Finalize Supply Chain’s Roadmap

Framework to design supply chain strategy

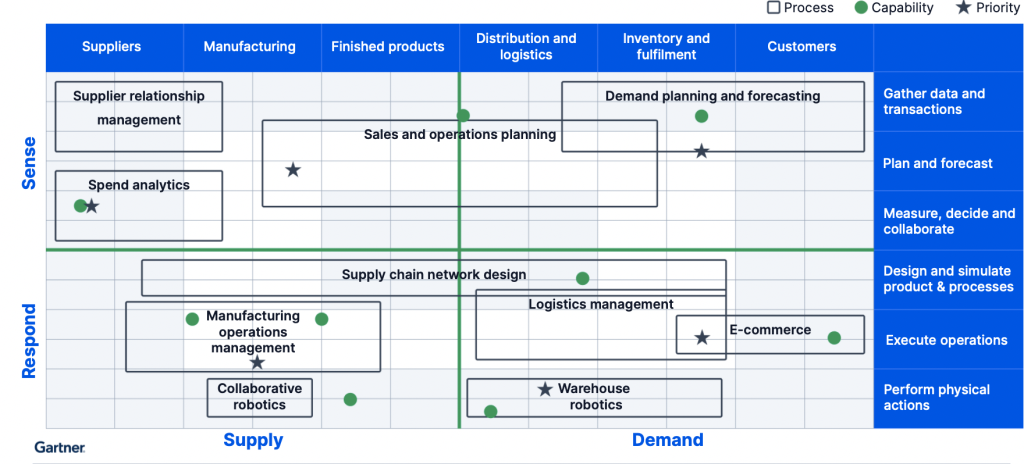

The framework is presented as a blank chart that can be customized for individual needs. The finished example shown by Gartner represents a comprehensive view of the supply chain strategy.

The framework is divided into two main sections: “Sense” and “Respond.” “Sense” refers to knowing what to do, while “Respond” involves executing and making things happen. The columns represent end-to-end supply chain working processes, starting from suppliers on the left and ending with customers on the right. The top part of the columns outlines activities like gathering data, transaction planning, forecasting, decision-making, collaboration, and design and simulation of products and processes.

The framework can be customized based on internal or external collaboration. It can be used to identify strengths, weaknesses, and priorities. The visual tool is recommended for Supply Chain management to communicate strategy to the board.

The Role of Sales and Operation Planning

Integration and visibility are crucial aspects of successful S&OP. It’s important to integrate various teams and departments, including sales, marketing, supply chain, R&D, and other stakeholders.

“The goal is to achieve a unified set of plans that everyone can work with collaboratively,” – said Akarat R., Managing Director at Inno Insight Co. “We need to bring the entire company together, emphasizing that S&OP is not solely about the supply chain but involves the entire organization.”

Digitalization efforts include Leveraging AI-based tools. Streamline AI-powered platform can aid in the digitalization of S&OP processes and effectively manage resources for growth.

What Constitutes S&OP Success?

Success in S&OP is determined by several key factors. These include:

The Bottom Line

The main goal of starting a digital transformation journey is to get ahead by using technology. The Streamline platform is helpful in making S&OP processes work better. It not only provides a comprehensive view of demand forecasting but also addresses challenges related to information sharing and trust-building in the dynamic landscape of digitalization.

Still relying on manual work in Excel for planning?

Automate demand and supply planning with Streamline today!

- Achieve optimal 95-99%+ inventory availability, ensuring you can meet customer demand consistently.

- Attain up to 99% forecast accuracy, getting more reliable planning and decision-making.

- Experience up to a 98% reduction in stockouts, minimizing missed sales opportunities and customer dissatisfaction.

- Cut excess inventory by up to 50%, freeing up valuable capital and storage space.

- Increase margins by 1-5 percentage points, boosting overall profitability.

- Enjoy up to 56 times ROI within one year, with a 100% ROI achievable in the first three months.

- Reduce the time spent on forecasting, planning, and ordering by up to 90%, allowing your team to focus on strategic activities.