User Guide

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

Add this page to your book

Add this page to your book  Remove this page from your book

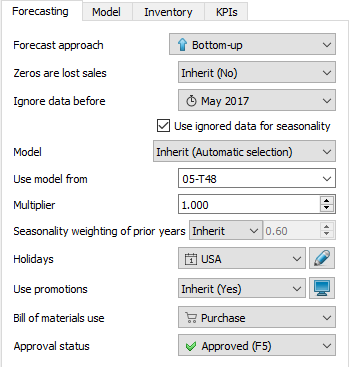

Remove this page from your book The Panel of the Demand forecasting tab contains a set of properties and settings for forecasting, inventory planning, and key performance indicators. These properties and settings are set and displayed for the currently selected node in the Tree view. The Panel consists of the following tabs:

The Forecasting tab holds options used as input information in the forecasting model building process. All the forecasting settings can be applied on an item, category or location level, generally, at every level of the tree. To put these settings into effect, re-forecast the project by clicking the Forecast button.

Here is the list of the forecasting settigs:

The Forecast approach control has the following options:

Bottom-up. This approach is used by default to build models for all nodes of the tree. It implies that forecasts on higher levels of the tree are calculated based on the forecast of lower levels as a simple sum, starting from tree leaves. Tree leaves models are standalone models that are calculated based on imported sales history.

Bottom-up. This approach is used by default to build models for all nodes of the tree. It implies that forecasts on higher levels of the tree are calculated based on the forecast of lower levels as a simple sum, starting from tree leaves. Tree leaves models are standalone models that are calculated based on imported sales history. Top-down. This method implies that the item's forecast is calculated based on the parent item model and the market share the item forms in its parent category. The market share of the item is calculated based on the simple moving average of n last periods. This method is useful when the item has no prior history and you need to have some reasonable predictions, for example, in the situation of launching a new product.

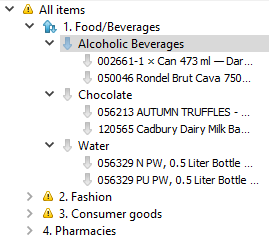

Top-down. This method implies that the item's forecast is calculated based on the parent item model and the market share the item forms in its parent category. The market share of the item is calculated based on the simple moving average of n last periods. This method is useful when the item has no prior history and you need to have some reasonable predictions, for example, in the situation of launching a new product. Top-down for child nodes. This approach combines the last two approaches in the following way: the Bottom-up method is applied to the selected item, and Top-down technique – to the item’s child nodes. In other words, in the example illustrated on the figure below, the forecast for the Food/Beverages category is calculated using the Bottom-up approach, and the Alcoholic Beverages, Chocolate and Water categories are forecasted based on the Top-down method.

Top-down for child nodes. This approach combines the last two approaches in the following way: the Bottom-up method is applied to the selected item, and Top-down technique – to the item’s child nodes. In other words, in the example illustrated on the figure below, the forecast for the Food/Beverages category is calculated using the Bottom-up approach, and the Alcoholic Beverages, Chocolate and Water categories are forecasted based on the Top-down method.

This option is helpful if you need to apply Top-down method to a huge set of categories and use the Bottom-up approach for the item on the top of them.

Zeroes are lost sales prevents periods with zero sales from demand underestimation. So, if zero sales are caused by a lack of inventory in the stock, choose the Yes option.

Zeroes are lost sales prevents periods with zero sales from demand underestimation. So, if zero sales are caused by a lack of inventory in the stock, choose the Yes option.

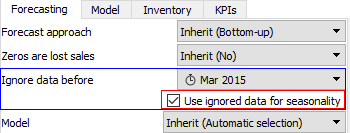

Ignore data before control allows reducing the item’s sales history that is used to build the forecasting model. All of the periods before the selected period are ignored. Data of the selected period is used to build the model. This option is helpful when you need to use a shorter length of history. For example, when sales volume has changed its level recently due to significant price change.

Ignore data before control allows reducing the item’s sales history that is used to build the forecasting model. All of the periods before the selected period are ignored. Data of the selected period is used to build the model. This option is helpful when you need to use a shorter length of history. For example, when sales volume has changed its level recently due to significant price change.

The Use ignored data for seasonality checkbox down the Ignore data before option allows taking ignored data into account to evaluate the seasonal components when the Seasonal & Trend model is built.

The Model control gives access to manual selection of model type.

Watch a video tutorial (2:36)

There are several options for the Model control:

Model = (Level + Slope * Time) * Seasonality

Use model from control allows using the model of another item to generate the forecast for the item. To do this, enter the item code of the source, or select it from the drop-down menu.

Use model from control allows using the model of another item to generate the forecast for the item. To do this, enter the item code of the source, or select it from the drop-down menu.

Multiplier. The result of the model will be multiplied by the multiplier. This option is used to increase or decrease the model output.

Multiplier. The result of the model will be multiplied by the multiplier. This option is used to increase or decrease the model output.

Seasonality weighting of prior years sets the weights for prior years' data. Weights for the other time-stamps are calculated by the exponential law. For example, 1 means that all the seasonal coefficients get the same weight equal to 1, so there is no exponential smoothing; 0 means that data of the last year only are taken into account to calculate the seasonal coefficients. Everything within the (0;1) is the result of exponential smoothing with different weighting. The default value is 0.6. This option can be used when you need to disable the exponential smoothing or replace the default weighting with your own.

Seasonality weighting of prior years sets the weights for prior years' data. Weights for the other time-stamps are calculated by the exponential law. For example, 1 means that all the seasonal coefficients get the same weight equal to 1, so there is no exponential smoothing; 0 means that data of the last year only are taken into account to calculate the seasonal coefficients. Everything within the (0;1) is the result of exponential smoothing with different weighting. The default value is 0.6. This option can be used when you need to disable the exponential smoothing or replace the default weighting with your own.

Holidays control enables taking into account holidays of the given calendar when Streamline is building the model for the item.

Holidays control enables taking into account holidays of the given calendar when Streamline is building the model for the item.

Bill of materials use parameter allows you to enable/disable manufacturing for the particular node of the data tree. This option gets into the action if bill of materials was imported.

Bill of materials use parameter allows you to enable/disable manufacturing for the particular node of the data tree. This option gets into the action if bill of materials was imported.

The Approval status control helps you to set which forecasts are satisfied, reviewed, or need to be revised in the future. The control differs in the set of options whether a tree leaf or branch is currently selected. If a tree leaf is selected it has the following options:

Approved. This option means that the forecast of the item is satisfactory and is approved. If you approve an item, its forecasting model will not be recalculated even if you change sale data or inventory information in the current period or add a new period by clicking the Update data button. Thus this model will be applied to the updated data.

Approved. This option means that the forecast of the item is satisfactory and is approved. If you approve an item, its forecasting model will not be recalculated even if you change sale data or inventory information in the current period or add a new period by clicking the Update data button. Thus this model will be applied to the updated data. Needs attention. This is a kind of reminder that is set when you are not sure which forecast correction to make at this time and have decided to make it later. An attention icon is added to the node and all the nodes above it to easily spot such items if the tree is collapsed. This status stays with the item whatever changes we made to the item's model in the Model tab.

Needs attention. This is a kind of reminder that is set when you are not sure which forecast correction to make at this time and have decided to make it later. An attention icon is added to the node and all the nodes above it to easily spot such items if the tree is collapsed. This status stays with the item whatever changes we made to the item's model in the Model tab.If a tree branch is selected, the Blank option is added to this control. This is the default option. Items (or categories) can have mixed statuses in this branch.

If you apply any of Undecided, Approved or Needs attention statuses to the branch, Streamline applies it also to all the nodes in the tree the branch.

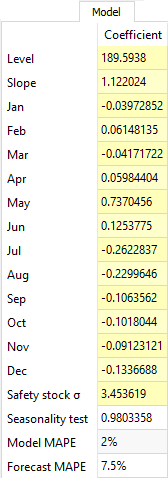

The Model tab shows the forecasting model structure and its coefficients in the table. You can adjust each of the coefficients of the model to align the forecast with your needs. Alternatively, to change the forecast, you can use the forecast overrides.

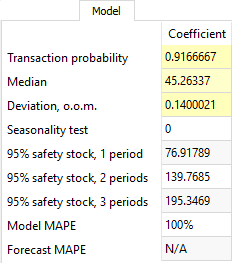

Information on this tab is available only for the tree leaves. There are two types of models in Streamline, the time-series model and the intermittent demand model.

Generally, the model looks like:

An example of the time-series model is shown in the figure on the right. All cells with the yellow background are editable in Streamline.

Calculation of the forecasts

The exact formula to calculate the forecast for a period is:

,

,

.

Where:

i is the number of the forecasted period;Nblue is the number of blue points in the Plot;seasonal coefficient is the seasonal coefficient of the month of i-th period. For weekly model, the seasonal coefficient is a linear combination of seasonal coefficients of two adjacent months; andholiday coefficient is a holiday coefficient that falls to this period.Example

Consider an example of forecast calculation. We will use the build-in Streamline example of Multi-location Demand and Revenue Forecasting having monthly data.

Let’s take a look at the first item 00266-1 in the East location, and change the model Slope from 0 to 1.5 for demonstration purposes.

The model is built based on fourteen periods from November 2015 to December 2016. The forecasts of this model range from January 2017 to December 2017:

Let’s calculate the forecast for January 2017. It’s the first forecasted period, thus i = 1.

Jan_2017 = (1748.014 + 1.5 * ( (14 - 1) / 2 + 1) ) * (1 - 0.281368) = 1264.26

Several criteria trigger the intermittent demand model in Streamline. One of them - when a part of zero demand periods exceeds 60% of demand history length.

This model always returns ‘0’ as expected sales, but calculates Safety stock based on stochastic model of log-normal distribution. That is, the intermittent demand model expects that a log-normally-distributed transaction occurs with a probability of p, and no sales with probability 1-p.

The Median, Deviation, and Transaction probability are the parameters of the distribution which are estimated. Alternatively, you can set them manually in the Model tab.

The Deviation is given in orders of magnitude (o.o.m.). One order of magnitude is 10 times greater/less, so Deviation is usually very small.

There are three calculations for the item safety stock right below the Seasonality test row. The first one shows Safety stock calculated for one future period based on service level of 95%. The second one, for two periods. And the last one, for three periods. As you see, the more periods safety stock covers, the larger it supposes to be.

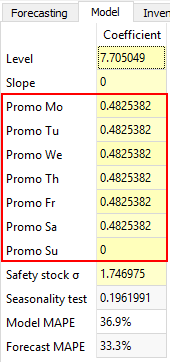

This model comes into play if the forecasted item has information on promotions imported and the data aggregation period is one week.

The promotional model is characterized by seven additional coefficients describing the future promotions weight into the generated forecasts (see figure on the right). Each of the coefficients corresponds to a particular day in the week.

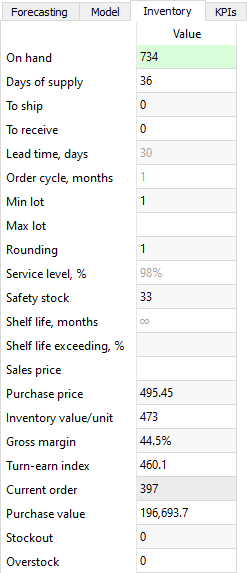

The Inventory tab shows most of the columns of the Inventory planning tab. The table below shows a description of them.

| Property | Description |

|---|---|

| On hand | Shows the current item on-hand quantity in stock |

| Days of supply | Shows how many days of the future demand, starting from the project date, the current On hand (including orders to ship) can cover |

| To ship | Shows the total quantity on open sales orders and backorders |

| To receive | Shows the total amount on open purchase, transfer, and manufacturing orders |

| Lead time | Shows the interval of time between transfer/purchase order placement and its receipt |

| Order cycle | Shows how often the item is ordered from the supplier or distribution center |

| Min lot | It is the minimum quantity of the planning item that you can order from your supplier or distribution center |

| Max lot | It is the maximum amount of the planning item that you can order from your supplier or distribution center |

| Rounding | It is a constraint that rounds the Net order amount up to the given quantity |

| Service level | It is the percentage of the time (in the long run) that the item is available in stock |

| Safety stock | Indicates the safety stock for the planning item |

| Shelf life | It is the desired time the item can be in stock |

| Shelf life exceeding | It shows the average percentage of the current order quantity that we might have to discard |

| Sales price | Shows the current sales price/unit for the planning item |

| Purchase price | Indicates the price you pay the supplier for the item in the supplier's currency |

| Inventory value/unit | Shows the balance value of one unit of the item in stock imported from your data source |

| Gross margin | Shows the gross profit margin of the planning item |

| Turn-earn index | Indicates the item gross margin accumulated over the last 12 months |

| Current order | It is the recommended quantity to order currently |

| Purchase value | Shows the value of the current order quantity in the supplier's currency |

| Stockout | It is the maximal expected inventory shortage during the Lead time period |

| Overstock | Shows the expected inventory level at the end of the Lead time plus Order cycle period |

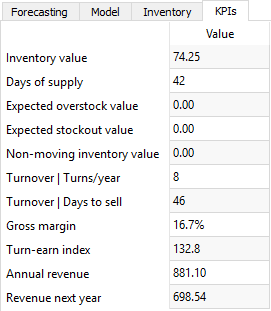

The KPIs tab shows important performance indicators of the item.