User Guide

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

Add this page to your book

Add this page to your book  Remove this page from your book

Remove this page from your book Assume we have locations imported. In this case, an inventory planning item is defined by a pair Location, Item code. There are two different safety stocks in Streamline depending on its configuration.

Depending on the inventory replenishment strategy, Safety stock or DC safety stock is an assessment of the reserve stock for:

Depending on the model type, the way Streamline calculates the Safety stock is different.

Streamline calculates Safety stock using one of the following methods for any model type, except for the intermittent model.

, (1)

where:

α is determined by the given Service level unambiguously;δ is the unbiased standard deviation of the model for the learning set. If Item code is sold, let's say, via n channels (we have n models), δ is calculated as:

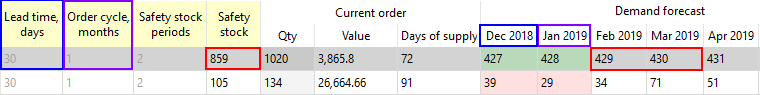

t is the Order cycle if the periodic strategy is used, or the Lead time in the case of the min/max replenishment strategy. The Order cycle and Lead time are converted to the data aggregation periods before the calculation.For example, if data aggregation period is one month (monthly data), Lead time is 30 days, Order cycle is 1 month, and Safety stock periods = 2, then Safety stock will be calculated as summed demand of the February and March (see figure below). This parameter can be also given as a fractional number.

The DC safety stock is computed using one of the same approaches as the Safety stock. The difference is only in the formula (1):

, (2)

,

where:

m is the number of locations that are supplied by the DC.δi is the unbiased standard deviation of the model for the planning item with i-th location for the learning set.α is determined by the given DC service level unambiguously.t is the DC Order cycle value if the periodic strategy is used, or the DC lead time value in the case of the min/max replenishment strategy. The DC order cycle and DC lead time values are converted to the data aggregation periods before the calculation.

Suppose T is the number of data aggregation periods in future for which Safety stock is calculated.

If T ≤ 1, then Safety stock is an estimation the following log-normal distribution:

, (3)

where:

Φ-1(·) – the quantile of standard normal distribution;You can also adjust the Deviation and Median parameters manually in the Model tab.

If T > 1, then the Safety stock is calculated in three steps:

1. Find the estimations and

.

2. Correct the estimations in the following way:

,

,

where:

Pt - the Transaction probability;VarB(T - 1) - the variance estimation of Binomial distribution.3. Calculate Safety stock using the formula (3) using the corrected estimations.

When T is fractional, there is no binomial distribution, but a formula for variance exists.

After Safety stock or DC safety stock has been calculated, Streamline refines it with one of the following ways:

Safety stock = MAX(Display qty, Safety stock) (default)Safety stock = Display qty + Safety stockIf Display qty is not imported, it is zero. You can switch between these methods in the project settings.

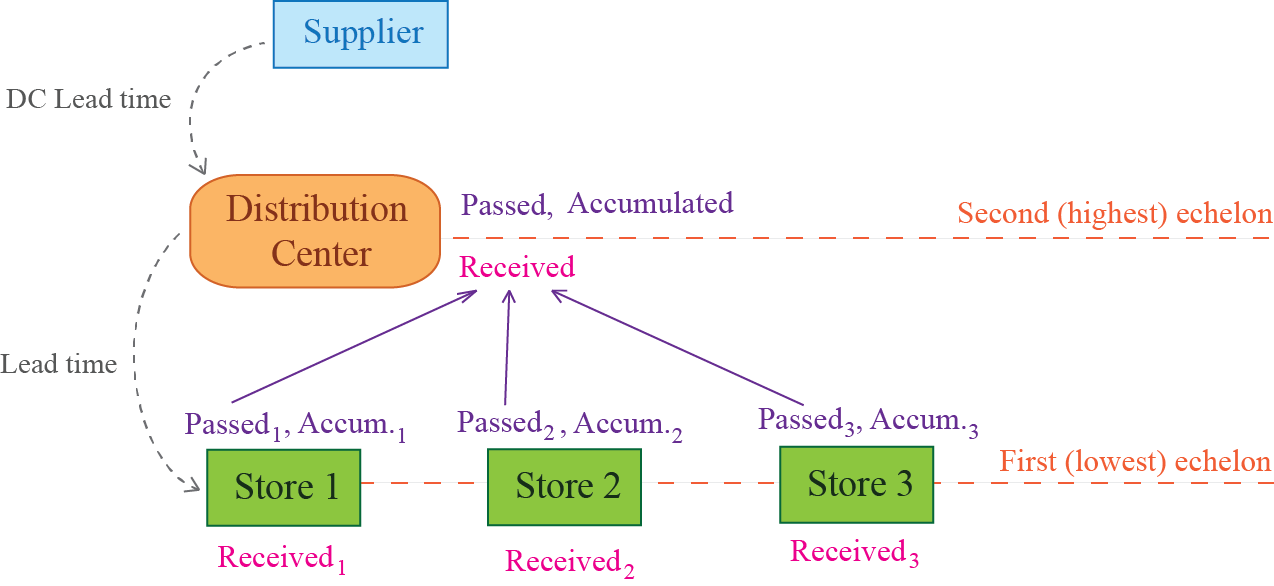

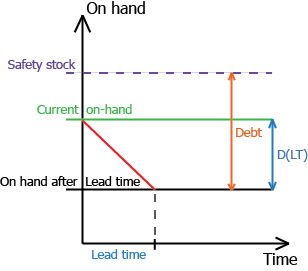

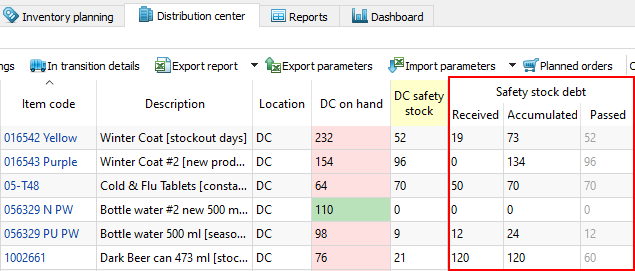

To replenish inventory in the two-echelon-model, Streamline uses the safety stock debt approach. Consider an example shown in the figure below.

There are four locations in the figure – one is a DC that resides at the highest echelon and the other three locations are stores, residing at the lowest echelon. Three safety stock characteristics are calculated for each location:

This debt is calculated for each planning item in the two-echelon model. Depending on the current on-hand level and demand during the lead time, safety stock debt passed may include:

Consider all the available cases.

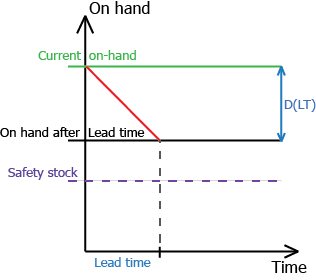

If no constraints (Min lot, Max lot, and Rounding) are applied, the calculation of the Debt passed follows the logic:

If on-hand ≥ safety stock + D(LT),

Debt passed = 0.

If safety stock ≤ on-hand < safety stock + D(LT),

Debt passed = MIN(safety stock, D(LT) + safety stock - on-hand)

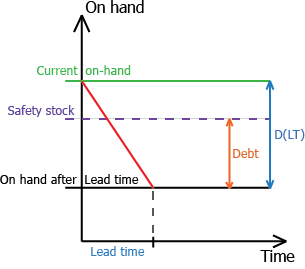

If on-hand < safety stock,

Debt passed = MIN(safety stock, D(LT) + safety stock - on-hand)

As you see, Debt passed can't exceed the location's safety stock.

The formula for the Debt received is:

,

where:

N – the number of locations at the lower echelon which are supplied from the DC;i-th location.The formula for the Debt accumulated is the following:

Debt accumulated = MIN[MAX{0, Forecasted consumption - DC On hand} + Debt received, Max SS debt],

,

,

where:

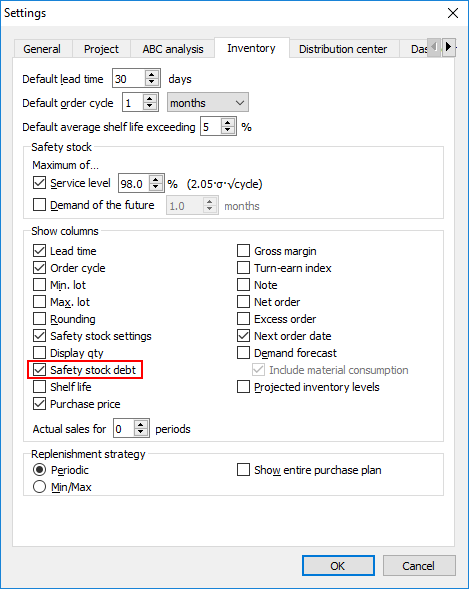

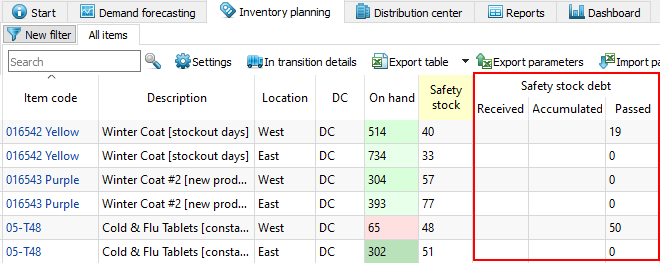

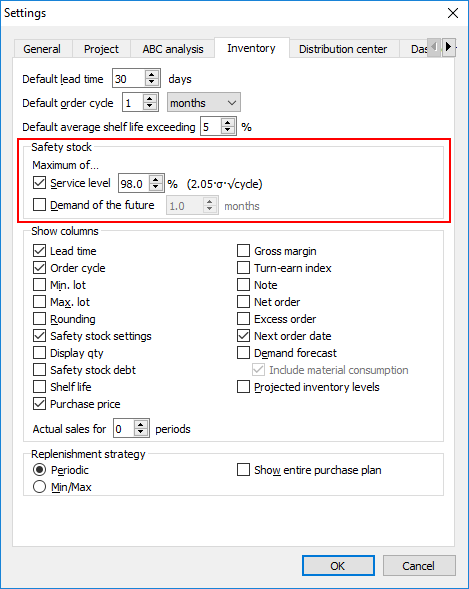

Demandi(DC lead time) – the i-th location forecasted demand during the DC lead time;N – the number of locations at the lower echelon;To demonstrate safety stock debts in Streamline, we use the built-in example Two-echelon Inventory Planning. To view safety stock debts for locations at the lowest echelon, check the Safety stock debt option on the Inventory tab in the Settings dialog (see figures below).

As you see, locations which are replenished from DCs have empty columns Received and Accumulated. The Passed column indicates the Debt passed to the upper echelon.

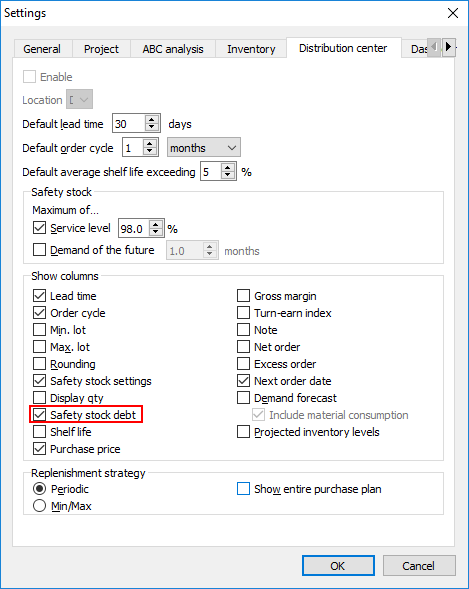

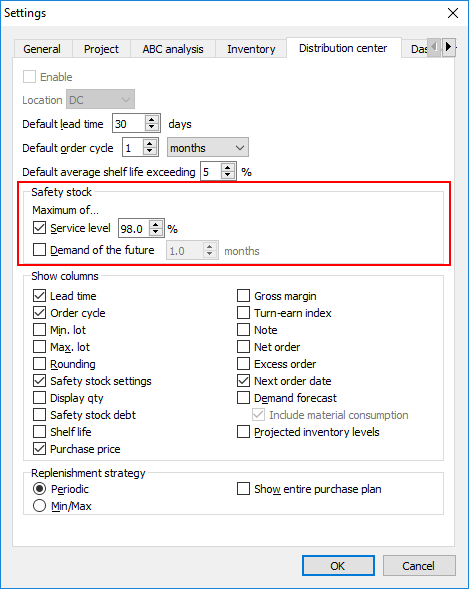

To view safety stock debts for DCs, check the Safety stock debt option on the Distribution center tab in the Settings dialog (see figure below).

Distribution center tab now shows an additional section Safety stock debt (see figure below).

The Received, Accumulated, and Passed columns refer to the Debt received, Debt accumulated, and Debt passed accordingly. Gray color in the Passed column means that these data are not used for calculating the DC outcomes.

Calculation methods for the Safety stock and DC safety stock are configured separately in Streamline.

To set up a calculation method for the Safety stock:

To set up a calculation method for the DC safety stock:

As we mentioned, the Safety stock and DC safety stock are calculated based on the given Service level and Safety stock periods parameters. There are several ways to set these in Streamline. To learn more about them, refer to the Replenishment parameters configuration methods.