User Guide

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

Add this page to your book

Add this page to your book  Remove this page from your book

Remove this page from your book The Settings dialog is used to configure Streamline and the currently open project in particular. All settings are divided into several groups. Each group is located on a certain tab of the dialog. These are:

To open up the program settings, go to the menu File > Settings.

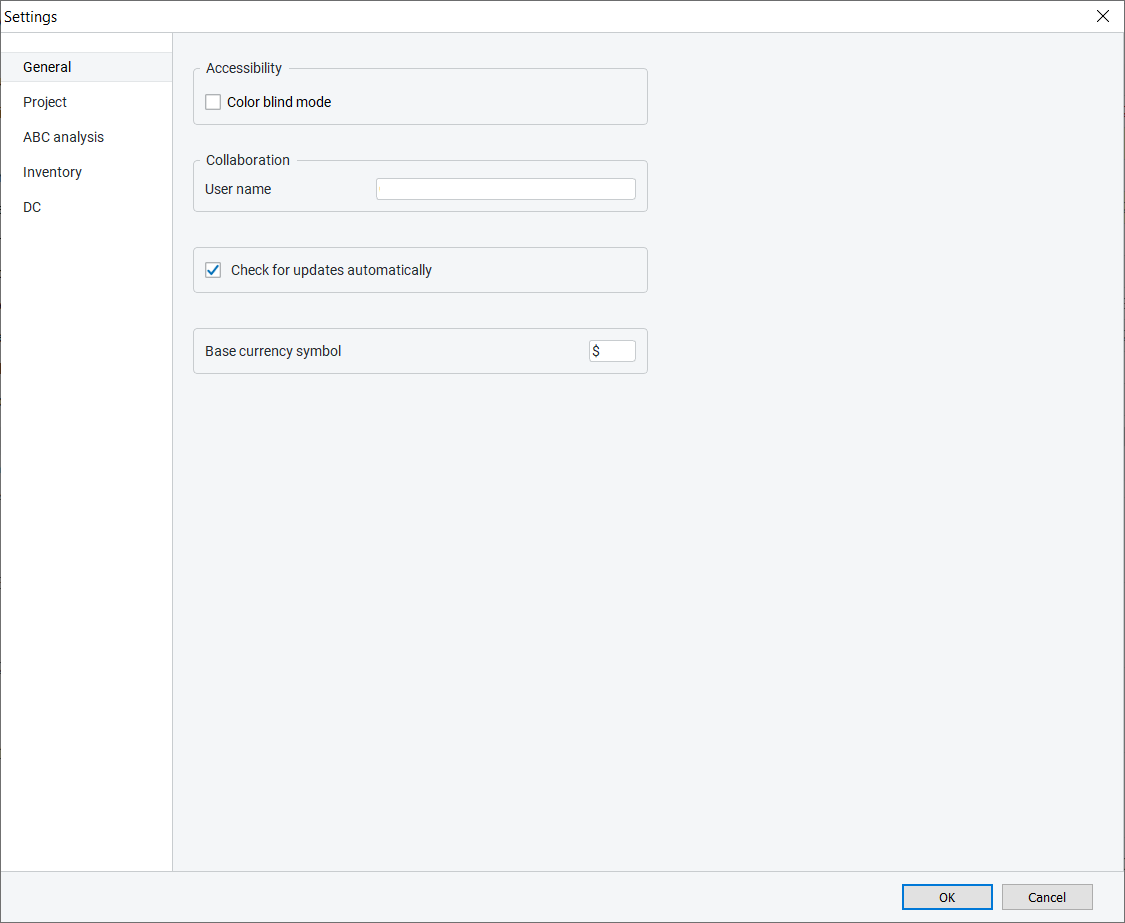

The General tab comprises the global settings of the program (see figure below).

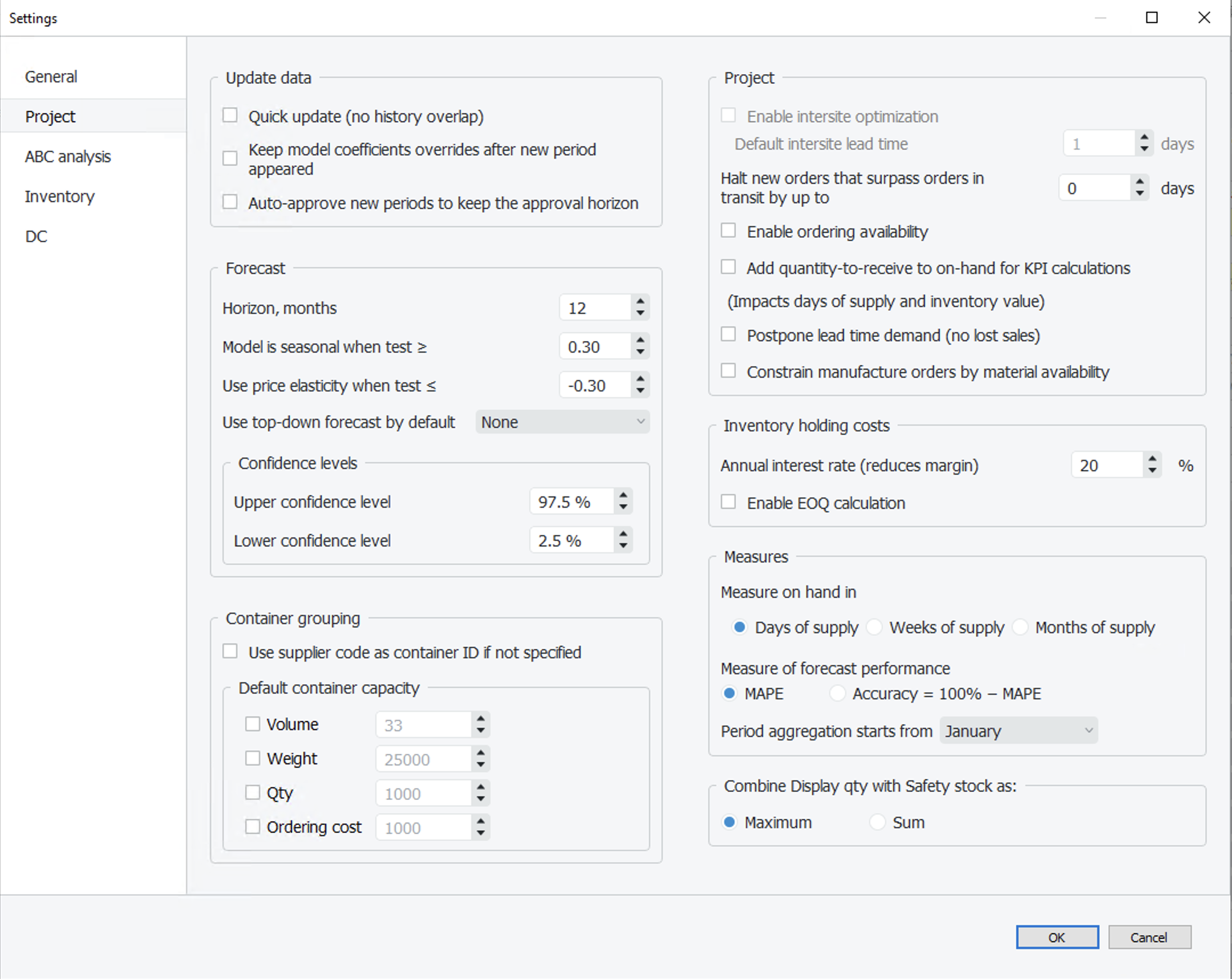

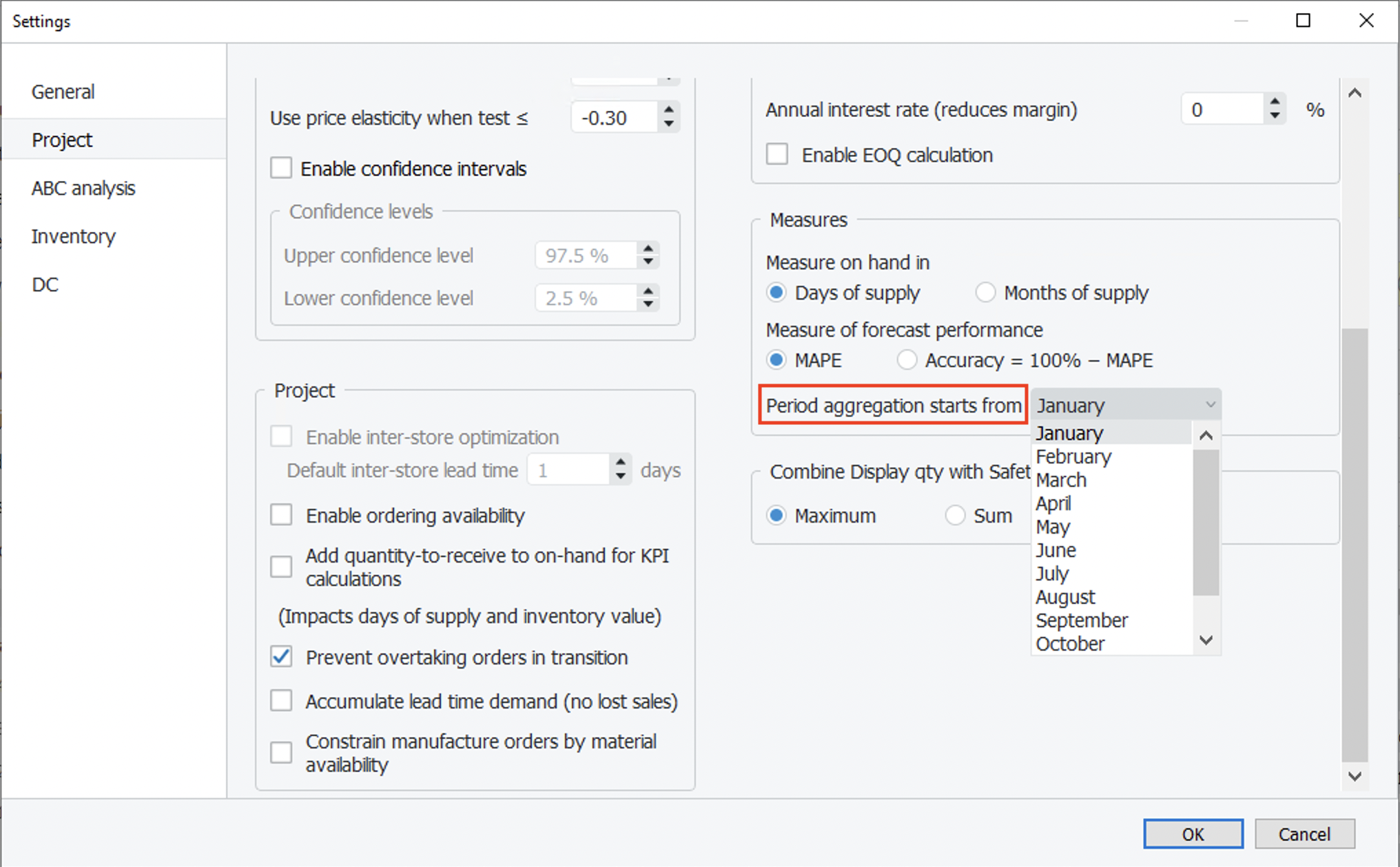

The Project tab contains settings to manage forecast generation, inventory replenishment, and customize reports.

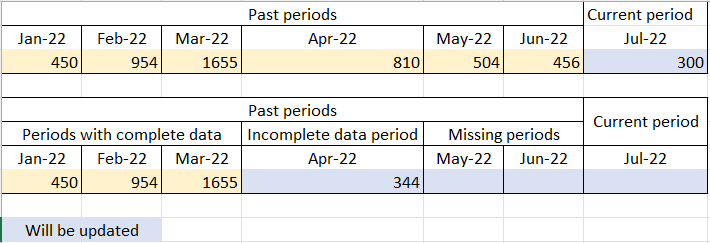

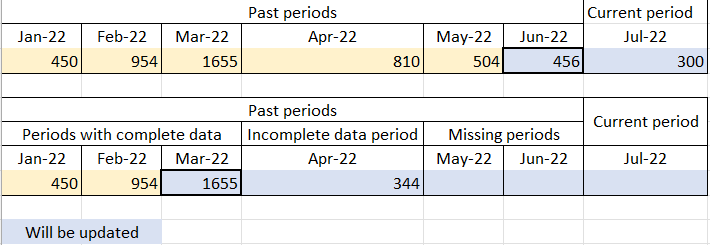

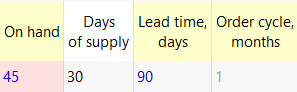

This option is unchecked by default, meaning that Streamline re-imports one period of the data before the latest one with data. Thus, Streamline overlaps by one period of the history when updates your data (see figure below).

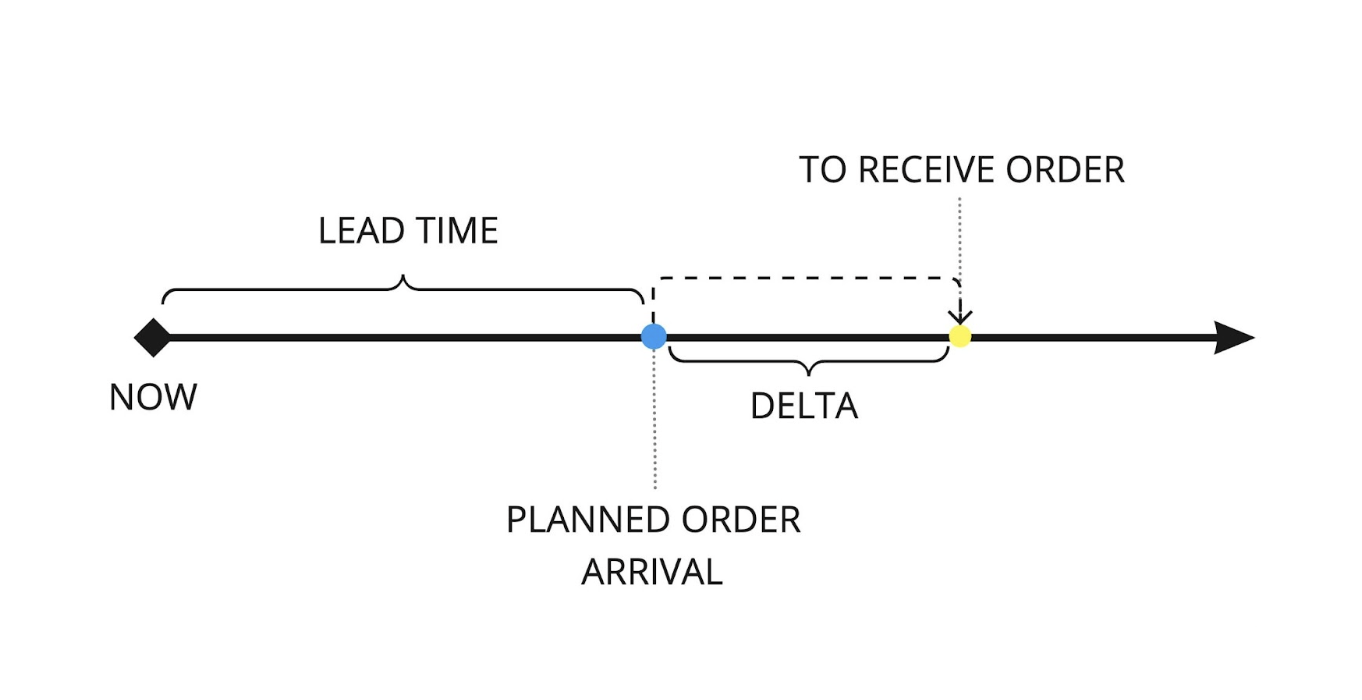

By default, this setting is disenabled, which means Streamline overtakes orders to receive if a time gap is enough for the arrival.

NB Only the periodic replenishment strategy supports this setting.

In other words if Days of supply < Lead time, Streamline won’t make up for the lost sales.

If you’d still like to order for the stockout months despite of delay, keep the box checked.

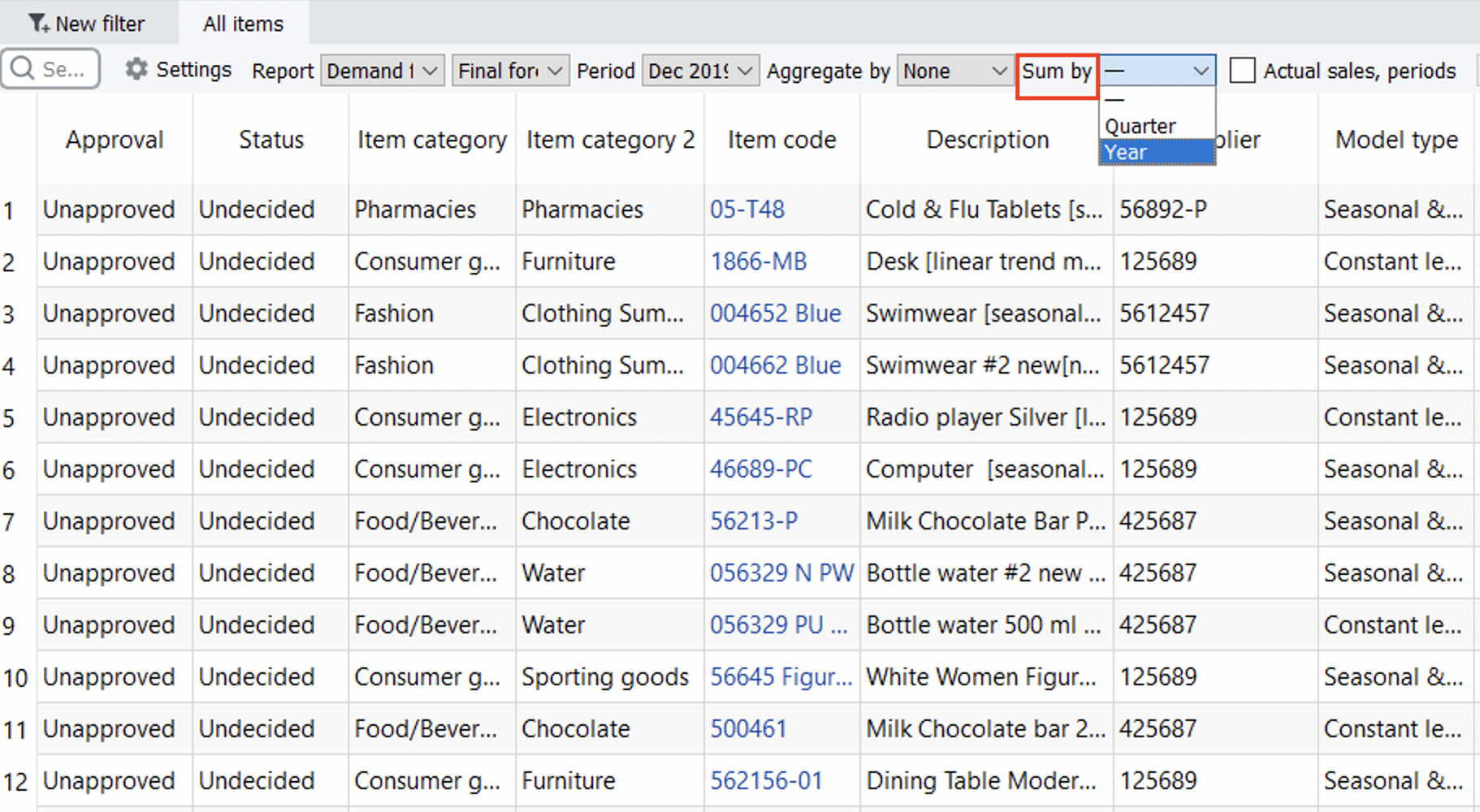

If the Period aggregation starts from option is set to the default value (January) in the Settings, the system simply aggregates the Report in this way so that the column displays data for the calendar year. However, if another month is selected in the Settings, the columns will take into account that the fiscal year starts with the selected month.

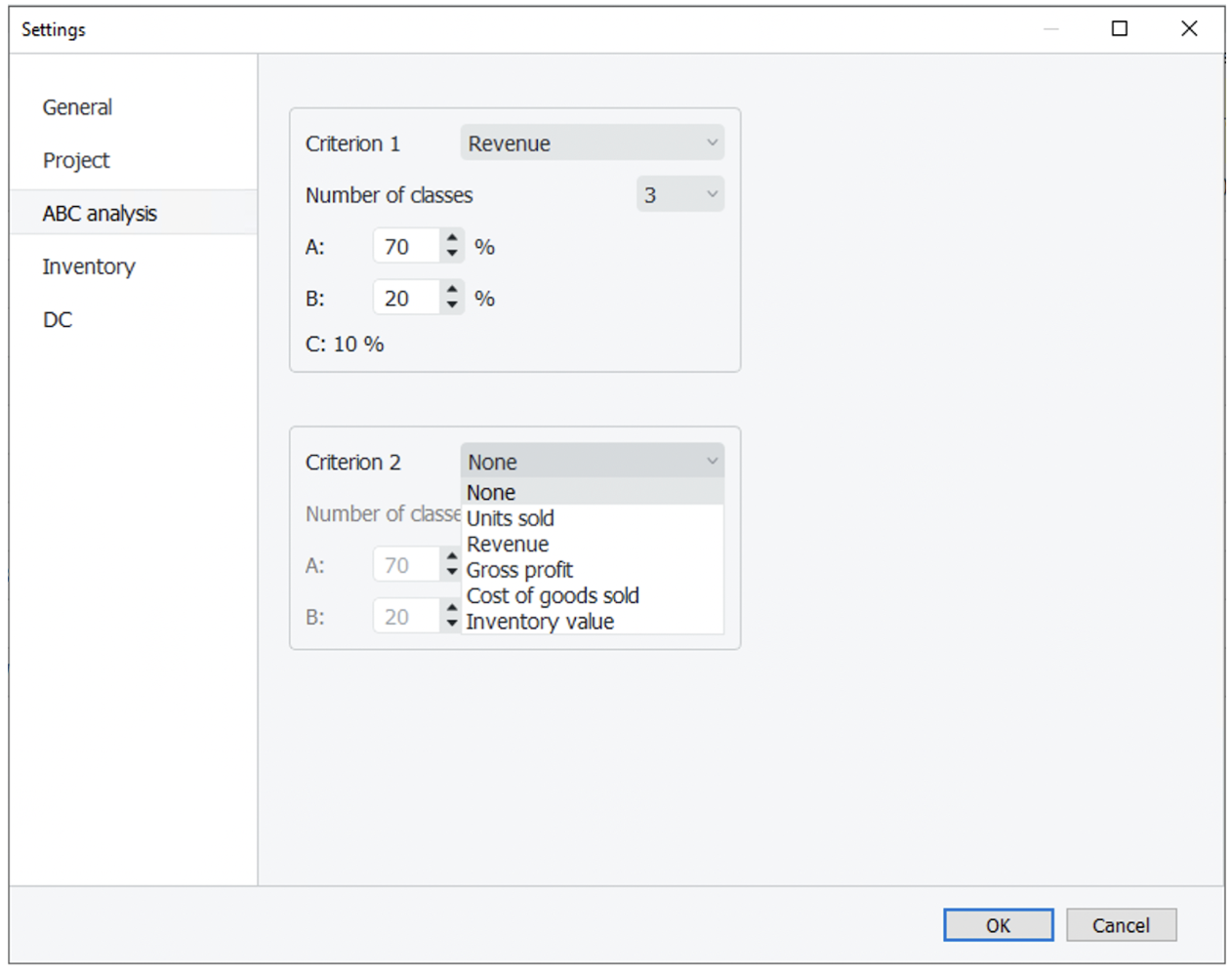

The ABC analysis tab is used to configure the ABC analysis that is automatically performed for your project. Streamline allows carrying out two-dimensional ABC analysis.

You can set the annual revenue percentage for each class Using the options below the Number of classes. For example, the percentage for A class set to 70% means that the class contains the items that give 70% of annual revenue in total. The percentage for the last class is a leftover from other classes and is calculated automatically.

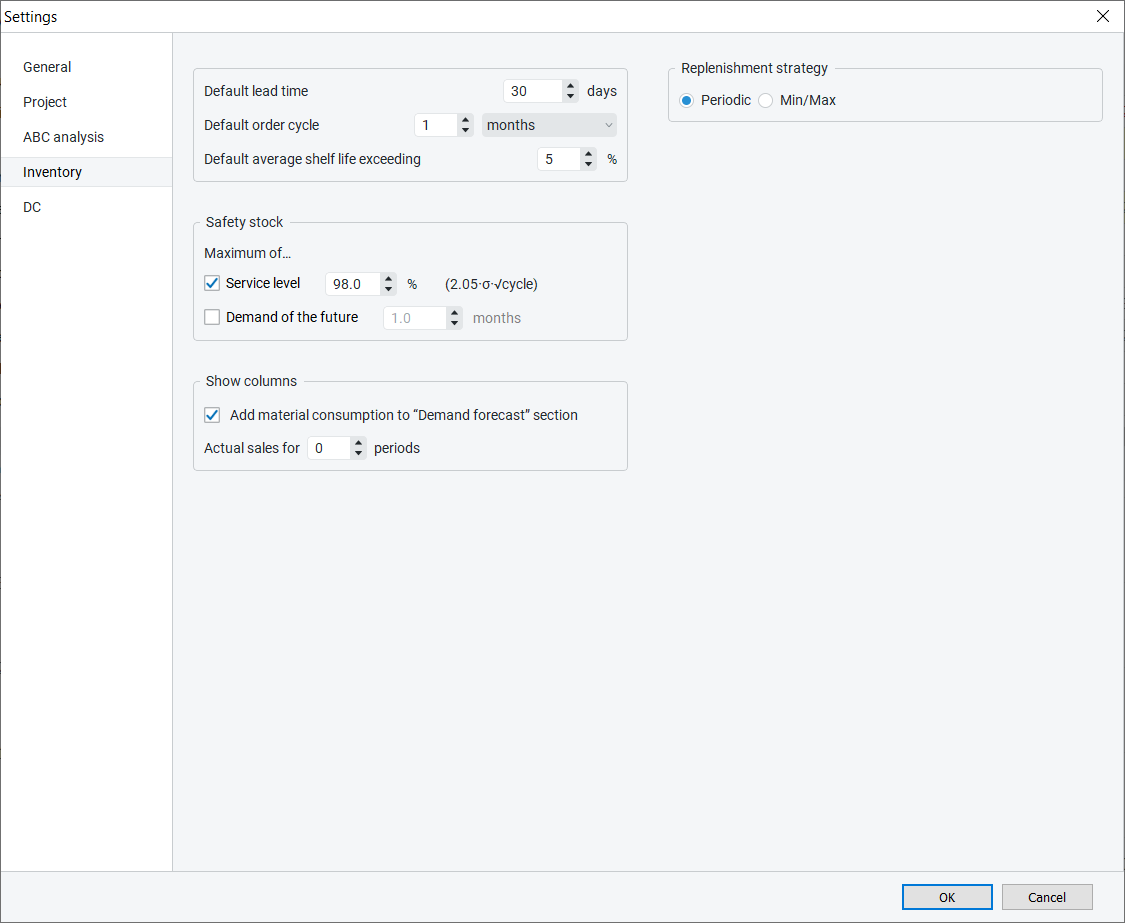

The Inventory tab The Inventory tab allows you to customize your inventory reports on the Inventory planning tab.

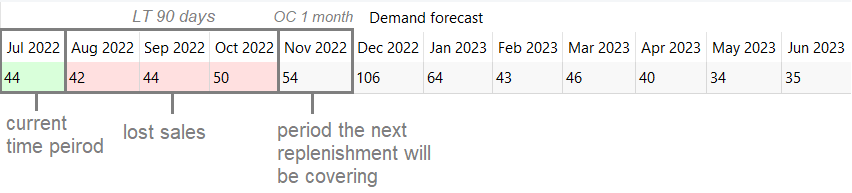

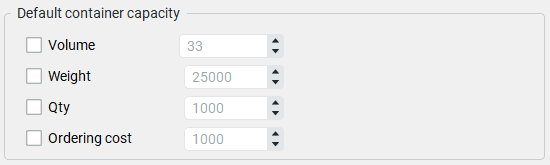

Default lead time option sets the default lead time in days for all the planning items.

Default average shelf life exceeding sets the default percentage of the replenished quantity that might have to be discarded because of Shelf-life limitation.

All defaults are applied to all planning items together.

Safety stock section defines how the Safety stock is calculated. It can be:

Safety_stock = α* δ *√t,

where:

α is determined by the given Service level unambiguously; δ is the standard deviation of the model error; t is the Order cycle value if the periodic strategy is used, or the Lead time value if the min/max approach is applied. The Order cycle and Lead time values are converted to the data aggregation periods before the calculation.n data aggregation periods coming after the Lead time plus Order cycle. Where n is given.When checked, the option Demand of the future in the Safety stock section, defines the period for which the Safety stock has to be accumulated.

Show columns section contains options that hide or show the particular column or section in the Inventory report table. When the Add material consumption to the “Demand forecast” section option is unchecked, the Demand forecast section of the inventory report shows only the final demand forecast based on the sales of items. Otherwise, the section shows the summed demand that includes manufacturing consumption and sales of the items.

Show Actual sales for option adds table section in the Reports that display sales history for the specified period. Streamline can drive the replenishment process using Periodic or Min/Max replenishment strategies.

Streamline can drive the replenishment process using Periodic or Min/Max replenishment strategies.

The periodic strategy is used when purchase orders are placed periodically, for example, once per month. In this case, Streamline provides a just-in-time ordering plan of what, when, and how much to order. The information is given in the Current order section of the Inventory planning tab. The application uses this strategy by default.

The min/max strategy is used when a purchase order should be placed when a stock level is about a certain replenishment threshold (reorder point), and you need to fill it up to some maximum level. In this case, Streamline provides the Reorder point and Max inventory information via Inventory planning. This information can be used then to draw your purchase plan.

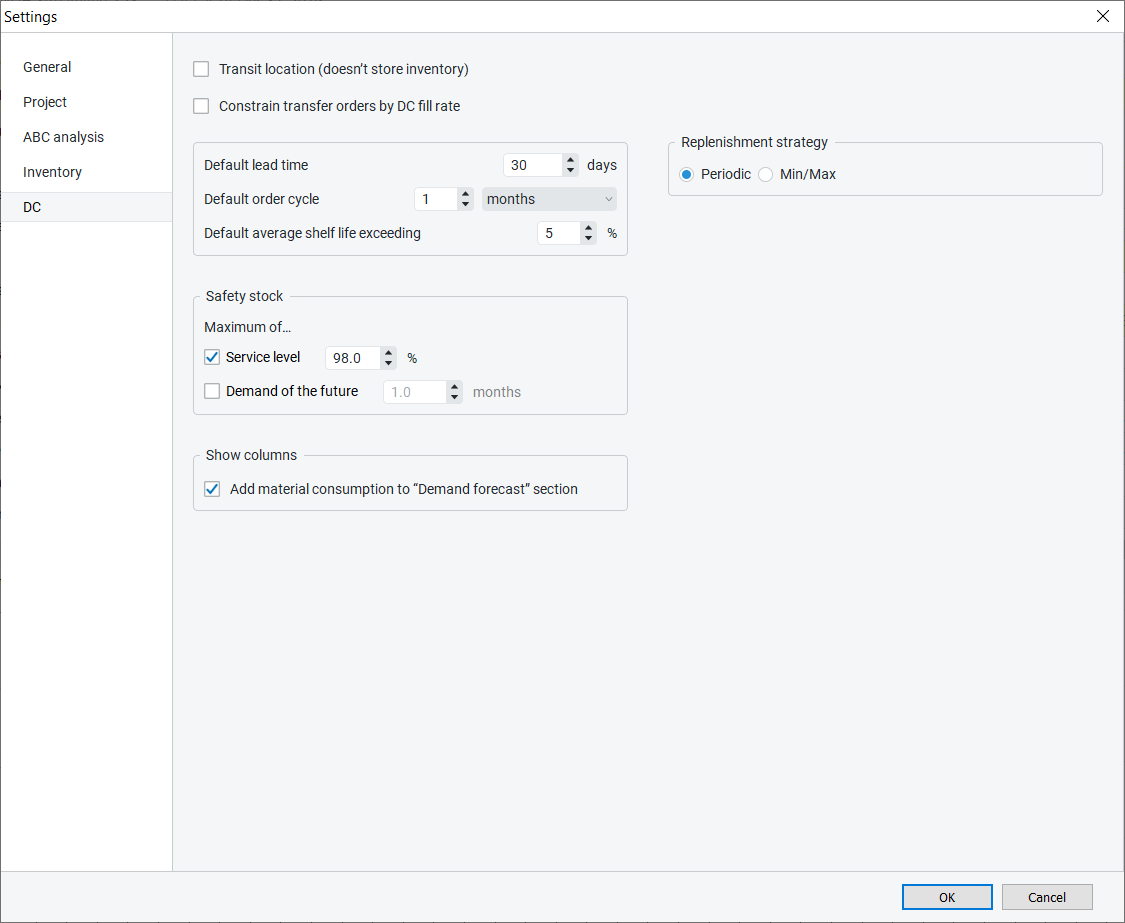

The Distribution center tab allows users to customize Streamline's distribution center settings.

If the option of Transit location is enabled, it disables stock in DC, which automatically sets the On hand, DC Safety Stock values, and Stock days to zero.

If you set the Constrain transfer orders by DC fill rate check box checked, the order quantity becomes restricted according to the item availability in DC. The DC Fill rate % column can be displayed as a column on the Inventory tab.

The Default lead time option sets the default lead time in days to deliver an item from supplier to DC.

The Default order cycle option sets the default interval of time between two successive replenishment orders made from DC to the supplier. It can be given in months/weeks (depending on the sales history aggregation period), or in days or lead times.

Default average shelf life exceeding sets the default percentage of the item’s purchase quantity that we might have to: send to a clearance sale, return to the supplier, and so on.

The defaults mentioned above are set for all the planning items at once.

Safety stock section defines how the DC safety stock is calculated. It can be:

DC_safety_stock = √(SS21(α,t) + SS22(α,t) + … + SS2m(α,t)), SSi(α,t) = α * δi *√t, i = 1, …, m,

where:

When the Add material consumption to the Demand forecast section is unchecked, the Demand forecast section of the inventory report shows only the final demand forecast based on the sales of items. Otherwise, the section shows the summed demand that includes manufacturing consumption and sales of the items.

Streamline can drive the replenishment process using Periodic or Min/Max replenishment strategies. These options allow you to set up the replenishment strategy for the DC.