User Guide

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

Add this page to your book

Add this page to your book  Remove this page from your book

Remove this page from your book

Streamline can account for product shelf life when it is generating a replenishment plan.

Shelf life is the recommended maximum time for which products or fresh (harvested) produce can be stored.

It should be less than the time period from the moment the item arrives in stock until the item expiration date. Streamline doesn't include Lead time into the shelf-life period.

Product shelf life can be also considered as:

shelf life limit qty.When Shelf life limitation is applied, Shelf life exceeding defines the percentage of the ordered quantity that, on average, will not be sold during the shelf-life period, and, probably, should be sent to a clearance sale, returned to the supplier, or write-offed.

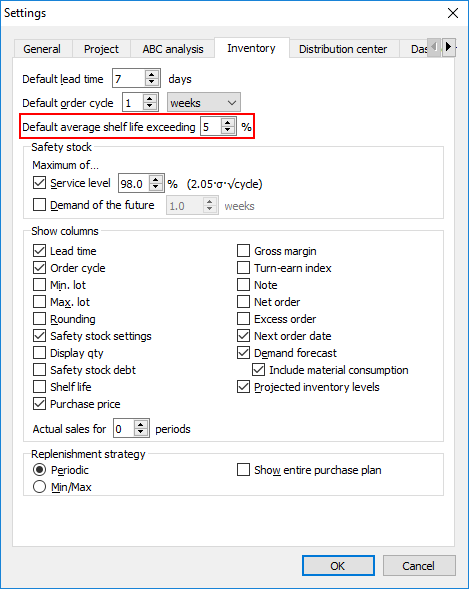

To be able to use this constraint in the optimization, you should import product shelf life data at the data connection step. By default, Streamline sets Shelf life exceeding to 5%.

There are three ways to set up the Shelf life exceeding in Streamline:

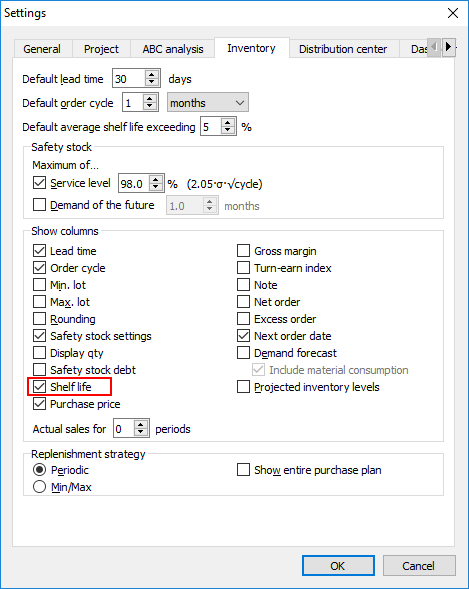

Streamline automatically notifies you when the Current order qty is reduced due to the given Shelf life limitation. All your inventory information is on the Inventory planning tab. By default, the shelf-life-related parameters are hidden. To show them:

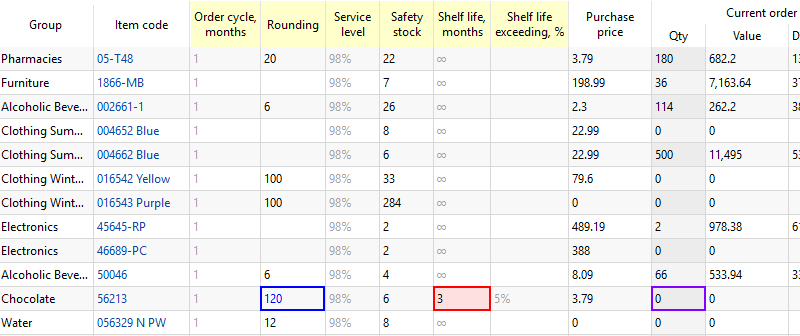

A red background for the cells in the Shelf life column of the table (see figure below) indicates that the calculated Current order qty has exceeded the shelf life limit qty. Streamline cuts this quantity down based on the shelf life limit qty in order to satisfy the given Shelf life exceeding percentage. Then, this limited amount is shown in the Qty column of the Current order section. In the example shown in the figure, it was cut to 0.

Shelf life-related cut-downs on an order might happen if some of the replenishment parameters make Streamline order more than you can sell during the shelf-life period. For example: