User Guide

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

1. Streamline Client

2.Streamline Server

3. Starting Up

4. Connecting data

5. Demand and Sales Forecasting

6. Inventory Planning

7. Reference

Add this page to your book

Add this page to your book  Remove this page from your book

Remove this page from your book This data piece is the item master data. It describes all characteristics of items required to plan your inventory in different cases, such as:

Despite all the above cases, basically, the primary goal of this data piece is to provide Streamline with the current on-hand quantity for every planning item. A planning item is defined by Item code or by pair Item code, Location, if you plan your inventory in different locations. Thus, the required data types for this data piece are shown in the table below.

| Data name | Description | Datatype |

|---|---|---|

| Item code | The item identifier. | String |

| Location | The code of location where Item code is stored. | String |

| On hand | The current on-hand of Item code in Location. | Integer |

Streamline allows you to plan your demand at a category level. It means that you are able to set specific forecasting options and make manual forecast overrides at a particular level of the category tree. To be able to do this, you should provide Streamline with the data types shown in the table below.

| Data name | Description | Datatype | Is not given | |

|---|---|---|---|---|

| Default | Provided | |||

| Item category, Item sub-category | Used to forecast by item categories. | String | Category with empty name | NULL or empty string |

| Location category, Location sub-category | Used to forecast by location categories. | |||

You can import as many categories as you need.

In addition to the Item code and Location, you can import data types displayed in the table below.

| Data name | Description | Datatype | Is not given | |

|---|---|---|---|---|

| Default | Provided | |||

| Item description | A description of the item. It is used to better understand what a particular item code means. | String | Empty string | NULL or empty string |

| Location description | A description of the location. It is used to better understand what a particular location code means. | |||

| Info field | Any additional characteristic of the item (e.g., color, size, texture). You can import an unlimited number of such fields. | |||

If your data source contains the relevant lead time and order cycle, Streamline gives you the ability to import them through data types indicated in the table below.

| Data name | Description | Given in | Datatype | Default |

|---|---|---|---|---|

| Lead time | If the planning item is sourced from a supplier, this is the average supplier lead time; if it is sourced from a distribution center (DC), this is the average lead time to deliver ordered items from the DC to the Location. These lead times are interpreted by Streamline as the interval of time between purchase/transfer order placement and its receipt. | Days | Integer | 30 |

| Order cycle | If the planning item is sourced from a supplier, this is the frequency you order from this supplier; if it is sourced from a DC, it is the frequency you replenish from the DC. | Data aggregation periods (weeks or month), days, or the Lead times. | 1 data aggregation period |

The accuracy of inventory reports can be improved, if you additionally provide the Lead time variance (see table below).

| Data name | Description | Given in | Datatype |

|---|---|---|---|

| Lead time variance | The variance of the Lead time. | Lead time units | Float |

To optimize the inventory, Streamline uses a lot of inputs such as Last on hand, Lead time, Order cycle, and other. Safety stock can be also considered as an input because it is used to determine the optimal ordering plan.

There two basic methods that Streamline uses to calculate safety stock. The first one is a well-known method based on service level. Streamline implements it and allows you to import service level for each planning item from a database. Another method is based on the future demand. Streamline allows you to set up the number of future periods of which demand is taken as the safety stock for a planning item.

A description of these data types is given in the table below.

| Data name | Description | Given in | Datatype |

|---|---|---|---|

| Service level | It is the probability of product availability in stock. It reflects the ability to sell the product to a customer. | Fractional number in the semi-open interval [0, 1) | Float |

| # of periods for safety stock | The number of future periods of which demand is used as the safety stock. | Data aggregation periods |

Streamline allows importing settings on how each item should be planned right from the data source. The table below shows which settings are available to set up.

| Setting | Description | Given in | Datatype |

|---|---|---|---|

| Inactive | Automatically sets the inactive model type to the imported item. | You can provide 1 or 'true', or 'yes' to put this setting in action, or 0, 'false', or 'no' - to ignore it. | Integer or String |

| Termination | Automatically sets the Auto & termination model type to the imported item. | ||

| Purchase for BOM | By default, if an item has a BOM, Streamline automatically treats this item as a manufactured one and builds a material procurement plan for its components. But, in the case, you want to purchase it, not manufacture, this setting tells Streamline to treat it as a regular item that is purchased. It also sets the material procurement setting to the Purchase for the imported item. |

Streamline can calculate key inventory indicators (KPI) such as expected stockout and overstock values, gross margin, and other metrics. To enable the calculations, you should provide one of the data types shown in the table below.

| Data name | Description | Datatype |

|---|---|---|

| Inventory value/unit | The balance value of one unit of the item in stock. It should be given in the base currency. It is preferable than the Item purchase price described below. | Float |

| Purchase price/unit | The last purchase price of the item in the supplier's currency. | |

| Sales price/unit | The current sales price of the item. |

The Purchase price/unit is also used to calculate the value of purchase orders' lines recommended by Streamline. You need to import either Sales price/unit or Transaction revenue for some of the KPIs (for example, the annual revenue, revenue next year, etc.).

Streamline allows you to import supplier information shown in the table below.

| Data name | Description | Datatype |

|---|---|---|

| Supplier code | The identifier of the supplier. | String |

| Supplier’s currency | The currency in which purchase orders are placed. | |

| Supplier's item code | Item code in supplier's stock-list that corresponds to your Item code. It allows Streamline to create purchase orders in supplier's item codes. |

Streamline allows you to account for constraints when optimizes inventory. There are two types of constraints, constraints on the item quantity that is ordered and constraints on the purchase order as a whole. Data types for the constraints are given in the table below.

| Data name | Description | Datatype |

|---|---|---|

| Display qty | The minimum number of units a shelf to display. This parameter typically arises in the retail business. You can control how this amount is used when final safety stock is calculated. | Integer |

| Constraints on item quantity ordered | ||

| Min lot and Max lot | Defines optional constraints on how few or how many of the planning item you can replenish from the supplier or DC with one order. | Integer |

| Rounding | This parameter rounds up the Net order quantity calculated by Streamline. This allows Streamline to take into account how many items are included in a carton, allowing the application to suggest exactly the right amount of the item to order. | |

| Constraints on purchase order | ||

| Group ID | Identifies a group of items on which minimum order constraints such as Group min/qty/weight/volume/cost are applied. If Supplier code is imported, it is automatically assigned to Group ID. | String |

| Group min. qty | The minimal quantity/weight/volume/cost for the item group required in order to replenishment/purchase order can be accepted. | Integer |

| Group min. weight/volume/cost | Float | |

| Weight/unit | The weight of one unit of an item. | |

| Volume/unit | The volume of one unit of an item. | |

| Container ID | An identifier that indicates to which container family the Item code belongs. | String |

| Container load weight/ volume/qty | Container characteristics such as maximal weight, volume, or quantity of items you can load into a container of the same Container ID. | Integer |

| Max containers | Defines how many containers of the same Container ID you can order at a time. | Integer |

Constrains on the purchase order are tied to the Supplier code. If no supplier code is given they are attached to an empty supplier. If a planning item is supplied from a DC and has Supplier code and some of these constraints given, Streamline neglects these constraints.

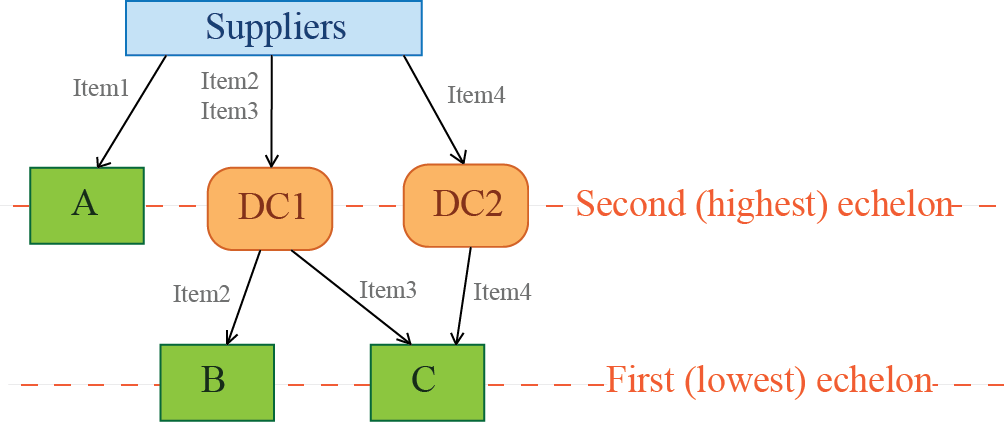

Streamline allows performing two-echelon planning.

If you have only one distribution center (DC), Streamline does not require you to provide any additional data, and you can set up all DC's options in the DC settings. In this case, however, there is no ability to account for the case when a location is supplied by the supplier directly (skipping the DC).

If you have several DCs, you can import and set up them using the Database connection. In this case:

You can import any number of DCs and set up which locations are supplied by a particular DC on an item basis. It means you should set up a triple (Location, DC name, Item code). For example, the triple (West, DC west, Dark chocolate) means that DC west supplies West location with Dark chocolate.

There are two limitations on the DC-location relation:

To set up the relations, the DC name data type should be returned with the Item info query (see table below). It indicates the name of the DC in the triple.

| Data name | Description | Datatype |

|---|---|---|

| DC name | The name of the distribution center that supplies the Item code to the Location | String |

Now, we describe the data types that the Item info query should return in order to Streamline set the relations properly.

As we explained previously, to set up a triple, the Item info query should return the following data columns: Location, DC name, and Item code. The table below shows an example of records that should be returned by the query in order to set up a DC-location-item relation.

| Location | DC name | Item code |

|---|---|---|

| A | DC1 | Item1 |

| DC1 | NULL | Item1 |

As you see, we need two records to be returned for each DC-location-item relation. The first one links location A to DC1, meaning that Item1 will be supplied by DC1 to location A. The second one declares DC1 as a location that stores Item1.

To set up a situation when an item is supplied to a location by the supplier directly (no DC involved), the query should return the record shown in the table below. The table shows example data.

| Location | DC name | Item code |

|---|---|---|

| B | NULL | Item1 |

Let's consider an example shown in the figure below.

In this case, the query should return the data shown in the table below.

| Location | DC name | Item code |

|---|---|---|

| A | NULL | Item1 |

| B | DC1 | Item2 |

| C | DC1 | Item3 |

| C | DC2 | Item4 |

| DC1 | NULL | Item2 |

| DC1 | NULL | Item3 |

| DC2 | NULL | Item4 |

Streamline can generate suggestions on inventory transfers between your stores if there is an overstock at least at one of them. By default, Streamline spends this overstock to fulfill current orders going up from the smallest to the largest, maximizing the number of replenished stores.

Additionally, Streamline allows you to put constraints on this rule by introducing the regions where the transfers are allowed. This is done using a data type that should be set for each location belonging to a region (see table below).

| Data name | Description | Datatype |

|---|---|---|

| Transfer region | The region the location belongs to | String |

Locations belonging to different regions can't have transfers. At the same time, transfers between locations of the same region are allowed.

These constraints are optional, thus, Transfer region data type can have gaps, meaning that the locations do not take part in any intersite transfers.

Streamline allows you to plan products having a limited shelf life. Product shelf life can be given in two units of measure (see table below).

| Data name | Description | Given in | Datatype |

|---|---|---|---|

| Shelf life, periods | It is the desired time you want the product to be sold for. | Data aggregation periods | Float |

| Shelf life, days | Days |

The Shelf life parameter is used as a constraint in the inventory optimization. It is the maximal limit on the current order quantity derived from the given shelf-life period and generated demand forecasts.